#ZERO

Beach Bum

- Location

- Florida - U.S.A.

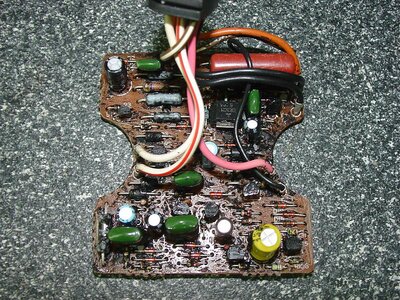

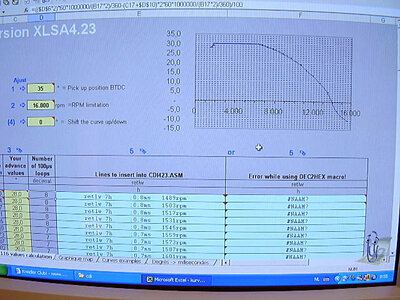

The stock CDI is not programmable. The curve is generated with an analog circuit, it can't be reprogrammed.

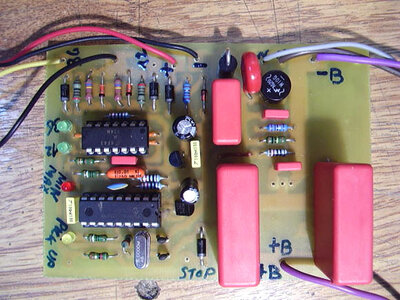

If you want programmable, look into MSD TL, Advent, or the WAX Racing CDI.

Why do you think the ignition timing curve can't be altered?

There's not a single microchip inside a CDI box?

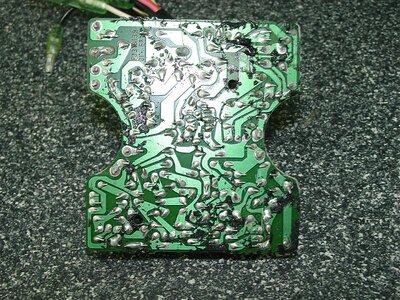

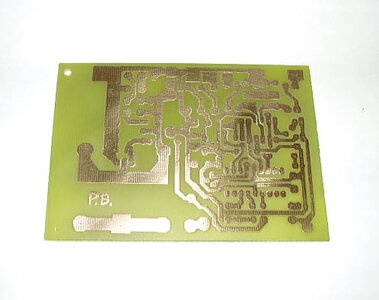

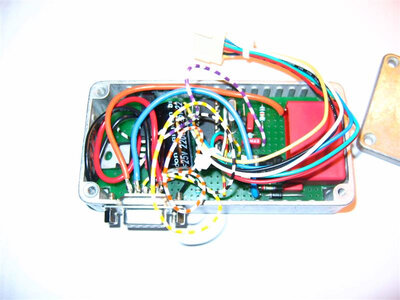

It took me two weeks having the box in an acid tank to dissolve the epoxy & white rock mixture and you're telling me that it can't be changed?