A bone stock 1100 engine with a stock pump setup in an sxr is honestly pretty slow. The advantage of the swaps is that the 1100 is really receptive to some simple mods and then they can become absolute rippers while still being reliable.

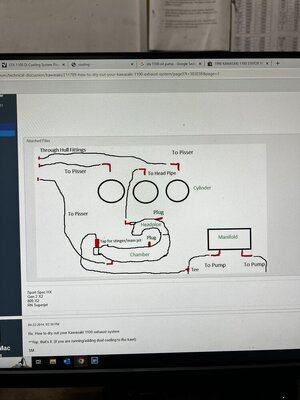

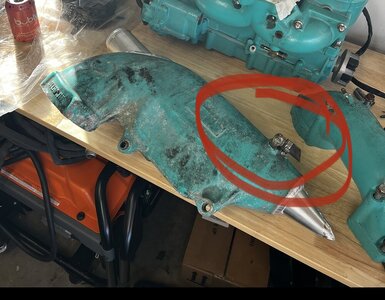

I can almost guarantee you will be disappointed if you install an 1100 and leave everything else stock. I’d highly recommend doing both timing advances (inside stator and jump ebox wires), do the dry pipe mod, mill the stock head to bump the compression (and add an extra water outlet on the front/rear cylinder), open up the waterbox (or use a rear waterbox) so it can breathe better, bore the stock nozzle to 82-84mm, and get a decent prop. If you have some extra money throw some mikuni carbs on with a good manifold and don’t look back. A good prop for a stock pump would be something in the range of 14-16 on the leading edge and 20-22 if using a skat trak and if using a solas something like 14-15 leading edge and 23-25 trailing edge. I didn’t really use the stock pumps a whole lot because upgrading to a 142mm or 145mm magnum pump really wakes them up a ton and allows them to hook up really well. There are a lot of combinations that work wel and your prop selection will need to be chosen in consideration with the other mods you do as well.

When the sxr1100 were all the rage in the racing world I ran an 82mm bore 1100 with mikuni carbs, Kommander intake manifold, dry pipe mod, light cleanup exhaust porting (no case porting) both timing advances, milled stock head approximately 145 psi, rear waterbox, a 142 mag pump with a skat trak impeller and it was 63-64mph all day long for a couple seasons and dead reliable. This was a pump gas 92 octane setup with no issues. You could get them into the high 60’s and low 70’s with lots of porting, advent ignitions, high compression (200+) and race gas. I was really happy with mine and got rid of the setup simply because everything went 4 stroke in racing. I have a 1500 GP1 now but nothing like the sound of a bunch of crisp 1100’s on the line.