OCD Solutions

Original, Clean and Dependable Solutions

- Location

- Rentz, GA

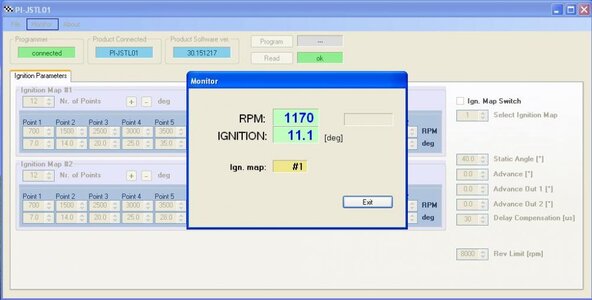

I was lucky enough to walk away from the 2016 Daytona Freeride with one of the newly released Total Loss systems introduced by Jet Ski Total Loss Inc.

This release brings forth one of the first affordable but still very powerful programmable packages at a fraction of the cost of MSD or ATP systems.

The package includes the control unit, solenoid, stator plate, 2 triggers, 2 smaller coils suitable for surf, the software and programming lead, all for a retail price of just $650. I am told that there will be different coil options available in the very near future as well.

The system was initially designed and proven with a Jetinetics flywheel which is available new for just $255 direct from Jetinetics.

As delivered, the system was setup with flatwater in mind so my first priority was to apply a little OCD to it and guarantee it will run day in and day out in a surf environment.

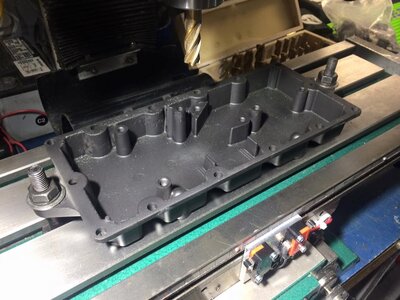

And here is the first peak of the surf ready unit installed into an OEM ebox!

And here is the completed surf build, ready for installation and water testing;

This release brings forth one of the first affordable but still very powerful programmable packages at a fraction of the cost of MSD or ATP systems.

The package includes the control unit, solenoid, stator plate, 2 triggers, 2 smaller coils suitable for surf, the software and programming lead, all for a retail price of just $650. I am told that there will be different coil options available in the very near future as well.

The system was initially designed and proven with a Jetinetics flywheel which is available new for just $255 direct from Jetinetics.

As delivered, the system was setup with flatwater in mind so my first priority was to apply a little OCD to it and guarantee it will run day in and day out in a surf environment.

And here is the first peak of the surf ready unit installed into an OEM ebox!

And here is the completed surf build, ready for installation and water testing;

Last edited: