Well look on the bright side. You should have a very nice ski when done, And you got one hell of a deal on the shipping . It going to be alright ( sounds like a good time for a group hug)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom/Hybrid WDK REV bottom with WDK RN topdeck(For my wife) is done!

- Thread starter McDog

- Start date

- Location

- South Florida

I did get quite a deal on the shipping. Good friends in the ski world are easy to find!

- Location

- South Florida

After.

- Location

- South Florida

The words would just be censored anyway. I'll get some pics and info up this evening.

- Location

- South Florida

The pic in the bottom middle shows the results of my frustration yesterday. I poured some two part foam in to drain to the bottom of the engine mount tray to give it support from underneath and to lock it in. I put a 45 pound weight on it flat and went to eat lunch. When I came back the damn foam had pushed up the tray about an inch on the front corner. The 45 pound weight did nothing to prevent this. I had to cut it out some so I could undermine the foam out from underneath it and then I poured some more foam in there with two 45 pound weights laying straight up so all the weight was there. It worked.

I finished fiberglassing the bulkhead, inserts, and driveshaft tube. I also installed the pump shoe.

Some carbon on the sides now and then it's time to put all the tubes back in the tray and start filling it with polystyrene.

I finished fiberglassing the bulkhead, inserts, and driveshaft tube. I also installed the pump shoe.

Some carbon on the sides now and then it's time to put all the tubes back in the tray and start filling it with polystyrene.

Attachments

-

2011-03-13_17-57-05_199.jpg41.4 KB · Views: 78

2011-03-13_17-57-05_199.jpg41.4 KB · Views: 78 -

2011-03-13_17-57-21_68.jpg51 KB · Views: 78

2011-03-13_17-57-21_68.jpg51 KB · Views: 78 -

2011-03-13_17-57-37_124.jpg44 KB · Views: 66

2011-03-13_17-57-37_124.jpg44 KB · Views: 66 -

2011-03-13_17-55-46_325.jpg46.1 KB · Views: 74

2011-03-13_17-55-46_325.jpg46.1 KB · Views: 74 -

2011-03-13_17-56-05_446.jpg33.9 KB · Views: 71

2011-03-13_17-56-05_446.jpg33.9 KB · Views: 71 -

2011-03-13_14-50-05_500.jpg41 KB · Views: 77

2011-03-13_14-50-05_500.jpg41 KB · Views: 77 -

2011-03-13_14-36-16_999.jpg40.1 KB · Views: 70

2011-03-13_14-36-16_999.jpg40.1 KB · Views: 70 -

2011-03-13_14-50-28_28.jpg56.5 KB · Views: 78

2011-03-13_14-50-28_28.jpg56.5 KB · Views: 78 -

2011-03-13_14-50-44_201.jpg52.2 KB · Views: 82

2011-03-13_14-50-44_201.jpg52.2 KB · Views: 82 -

2011-03-13_14-36-02_486.jpg38.4 KB · Views: 67

2011-03-13_14-36-02_486.jpg38.4 KB · Views: 67

Last edited:

- Location

- South Florida

Carbon fiber is in the engine bay. I hate working with carbon fiber. It doesn't like to stick. Engine bay is done except for priming and appliance epoxy enamel paint.

All the tubes are in. I hate working with 5200. Such a freaking mess and it doesn't wash off, it wears off. The scupper tube is a little small with 1 inch id tubing but that is the same size as the versaplug max opening so it's all good.

Cut the footholds to get ready to do some changes.

The build hit a delay when my basement flooded two weeks ago. I ended up with a back hoe in my front yard and having to redo all my landscaping and 6 pallets of sod. I also had to repair 6 sprinkler system leaks. kind of tired of digging right now too.

I just want to ride....but I'm a long way off.

All the tubes are in. I hate working with 5200. Such a freaking mess and it doesn't wash off, it wears off. The scupper tube is a little small with 1 inch id tubing but that is the same size as the versaplug max opening so it's all good.

Cut the footholds to get ready to do some changes.

The build hit a delay when my basement flooded two weeks ago. I ended up with a back hoe in my front yard and having to redo all my landscaping and 6 pallets of sod. I also had to repair 6 sprinkler system leaks. kind of tired of digging right now too.

I just want to ride....but I'm a long way off.

Attachments

- Location

- South Florida

Big Kahuna

Administrator

- Location

- Tuscaloosa, AL

uh, what is with the metal strapping??? Tell me your not leaving them there.

uh, what is with the metal strapping??? Tell me your not leaving them there.

I'll field this one Shane

Harrison , Maybe you need a refresher .... it's the foot hold of tomorrow , everyone is going to metal straps these days .

Seriously , The metal straps are being utilized to haphazardly hold , various pieces of odd angled fiberglass a waiting the

biax MASTER'S gentle yet firm touch .

- Location

- South Florida

Fiberglassed the tray today. Gonna clean it up with a dremmel and get it off to waternut for paint tommorow.

Attachments

- Location

- South Florida

Microballons and epoxy as a waterproof filler. It's not there on the pictures taken of the tray before I started fiberlassing.

- Location

- South Florida

Weighed it today at Waternut's. 105 pounds. I really thought it would be lighter.

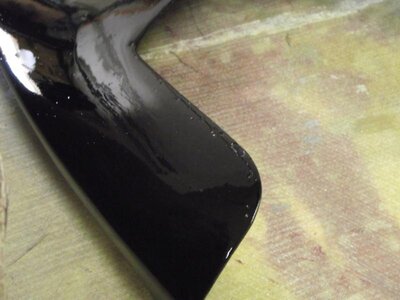

Pinky 2.0 has some fairly serious cracks that weren't visible until the paint came off. I started grinding them down deeper and deeper and noticed that they were disapearing. Due to this being a fairly critical location on the hull, I laid a bunch of fiberglass inside. Hopefully it holds and doesn't show once cleaned up.

Attachments

- Location

- South Florida

Holy crap. I don't know how I missed that. This project has been the gift that just keeps giving. Thanks so much for doing some fiberglass repair with the bodywork. I really appreciate it.

Paint is mostly done. The hull is done. There is something on the hood in a couple small spots that is causing some funky issues. Even primer didn't stick to it so I'll give that another sanding and try again.

Is the pitting on the very inside edge of the nose piece going to bother you?

Is the pitting on the very inside edge of the nose piece going to bother you?

Attachments

- Location

- South Florida

I definitely prefer it without pitting but also I'm sure you are tired of painting and have your own projects to do. Is that the superfreak nose or the wdk nose?