You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

XI

- Thread starter mikesx

- Start date

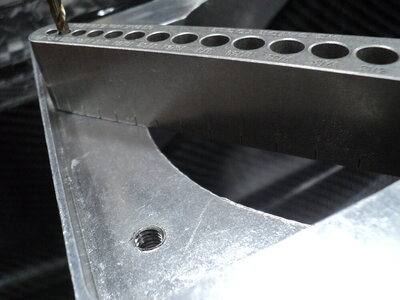

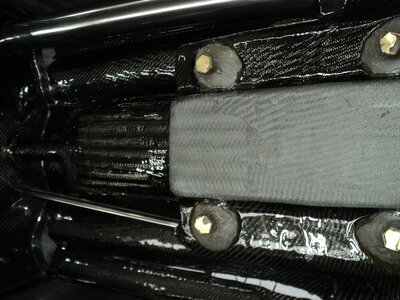

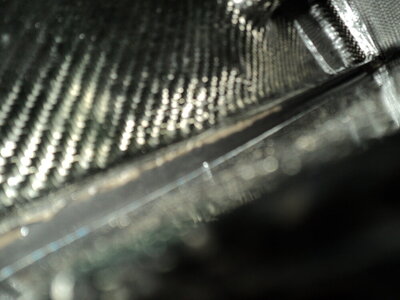

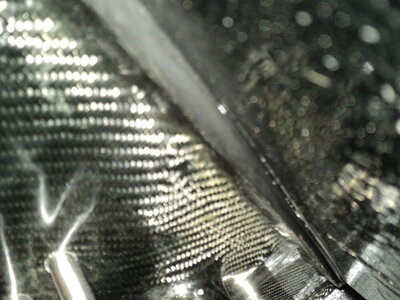

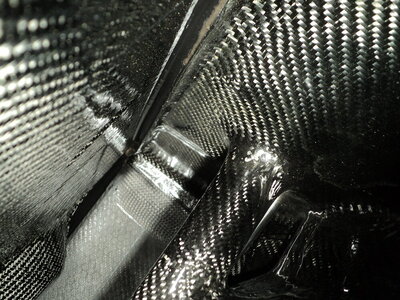

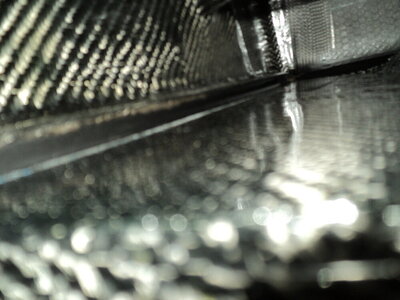

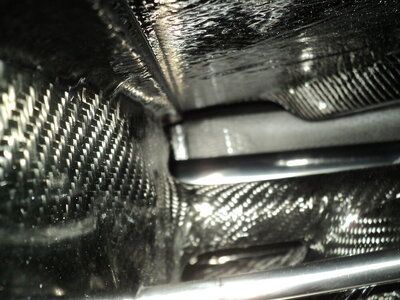

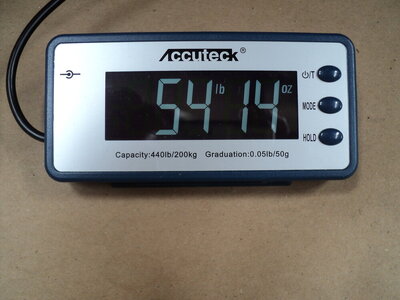

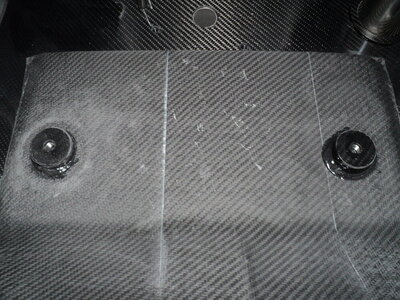

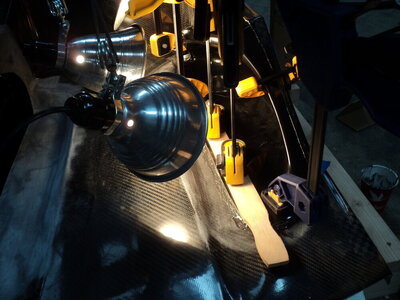

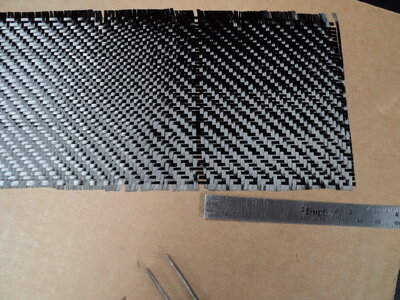

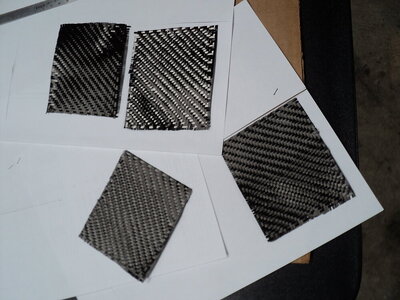

So now the day of reckoning. Bonding on the top deck. Not a lot of pictures because there literally was no time. I live half an hour from Tigercraft so Tony offered me the use of his air powered mixing tube dispenser after I told him I was going to just buy a manual one. He just said " You don't want to do that, I'll lend you mine". Best offer I ever got, from a guy , lol. When I picked up the hull he said I would need 3 tubes, I bought 4. So I picked up the air powered dispenser Friday night for a Saturday bonding session. I recruited my buddy Flash-Fx for help since he had some experience with putting together hulls. Luckily our buddy Wavehog tagged along. I had everything ready , plastic spoons putty knives , rags, cleaning supplies, etc. I had clamps ready even though Tony said I wouldn't need them. The stuff Tony uses to bond hulls is 40 min cure, EXACTLY 40 min. So we hooked up the gun, pulled the trigger, and..........it started dispensing.... slowly. Turned up the air to 90 max listed on the gun, no faster. This is where I'm glad I had Flash there because the first thing he did was hit a timer on his phone. For the next 30 minutes my finger only came off the trigger to switch out tubes. I dispensed , Flash and Wavehog spread. At 32 minutes we placed the deck on, at 40 minutes, the show was over. White knuckles, not for the faint of heart, think twice before you ever consider trying this.

Last edited: