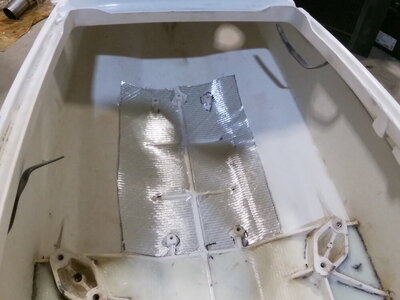

Well, I got NOTHING done yesterday. Sunday, 6pm, fine but sneezing every now and then. 7:30, sniffling a bit along with the sneezing. DAMN! What did my wife spray in the air that maybe I'm allergic to? I have severe grass and pollen allergies anyway. 9:45 pm........FULL BLOWN HEAD COLD! Man, that thing came on strong and fast! Took Nyquil and slept a LOT of yesterday. Today, a bit off feeling still but my ears cleared out, sinus pressure is gone, nose quit running. So I went down to the shop and got a little bit done before started getting a headache.......time to quit......don't overdo it! I got another layer of 17oz biax in the motor mount areas, and laid some down under the gas tank area. Also mixed in some foam bb's and filled a bit inside the battery tray. I really don't like all these areas that can pool water.