holygoat

Site Supporter

- Location

- Indiana, USA

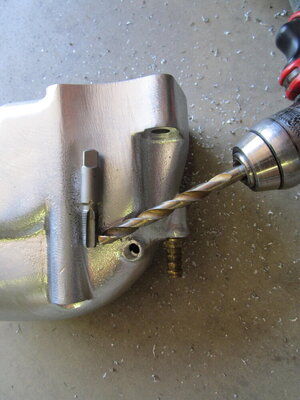

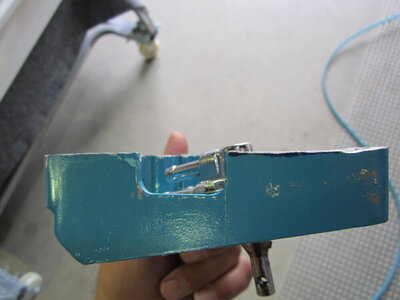

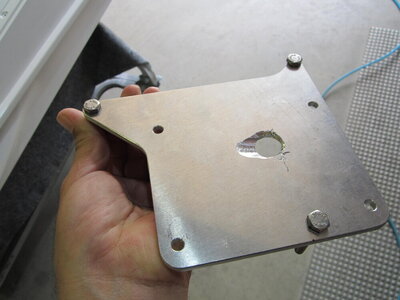

I just came in, I'm just exhausted. Temp in my shop.....in front of fans..= miserable! Anyway, I got some brackets screwed down. I got some pads cut and glued down. I marked and V cut the center pad under the gas tank so it would sit flat in the hull. Got the waterbox strapped in and exhaust hose run. Also got the pole bracket and fuel neck installed. Now I pretty much can't do anything until the driveline is installed. DANGIT!

What material for those pads? Looks nice. Glued down with Weldwood?