You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Super Jet 771 SuperJet Build

- Thread starter munki63

- Start date

D-Roc

I forgot!

- Location

- Dirty River Rider

unless you buy a complete motor with carbs assembled and run their timing, pipe, prop etc it will not be turn key. My buddy got one that was turn key, ran mint outta the box. I though you where running rich and needed to lean it out a bit, keep going with the carb tuning, you will get it dialed in soon enough.

- Location

- South Florida

I think your issues have been the motor all along and not the prop. I had issues with air getting in my fuel lines from a defect inside the fuel lines I couldn't see. It was cracked/slit just on the inside. It sounds like there is an air leak somewhere. I had the same type of power issues until I replaced all the fuel lines with crappy clear ones and it worked fine. This was after multiple motor tear downs and leak tests. I had another motor that kept melting pistons that held pressure just fine, but apparantly it was pulling air in through a bad crack seal. The builder said it would have shown up with a negative pressure test by using a brake bleeder from Autozone.

I ran a 10/16 Hooker with a wetwolf cone and 85mm nozzle on a LPW 771 with msd enhancer and later with total loss in a stock hull in the past and it was fine. I am running a 10/16 Hooker with a TBM cone and 85mm bored nozzle now with my XS 781 and an EPIC and it feels perfect too. I'm betting it loads more than a 11/17 this way. I don't think the prop differences are as extreme as the symptoms you are dealing with.

I ran a 10/16 Hooker with a wetwolf cone and 85mm nozzle on a LPW 771 with msd enhancer and later with total loss in a stock hull in the past and it was fine. I am running a 10/16 Hooker with a TBM cone and 85mm bored nozzle now with my XS 781 and an EPIC and it feels perfect too. I'm betting it loads more than a 11/17 this way. I don't think the prop differences are as extreme as the symptoms you are dealing with.

- Location

- Algonac, MI

do you think the 10/16 would be good for a stock 701? is it good for low end? im planning to get the prop and then gradually upgrade the motor with a b pipe and msd enhancer with an ada head. or would the 9/15 be better. i asked dave and he recommended the 10/16 for a stock motor but what about when i get into the mods. will the 10/16 still be a good impeller for low end hit?I think your issues have been the motor all along and not the prop. I had issues with air getting in my fuel lines from a defect inside the fuel lines I couldn't see. It was cracked/slit just on the inside. It sounds like there is an air leak somewhere. I had the same type of power issues until I replaced all the fuel lines with crappy clear ones and it worked fine. This was after multiple motor tear downs and leak tests. I had another motor that kept melting pistons that held pressure just fine, but apparantly it was pulling air in through a bad crack seal. The builder said it would have shown up with a negative pressure test by using a brake bleeder from Autozone.

I ran a 10/16 Hooker with a wetwolf cone and 85mm nozzle on a LPW 771 with msd enhancer and later with total loss in a stock hull in the past and it was fine. I am running a 10/16 Hooker with a TBM cone and 85mm bored nozzle now with my XS 781 and an EPIC and it feels perfect too. I'm betting it loads more than a 11/17 this way. I don't think the prop differences are as extreme as the symptoms you are dealing with.

if you use a spacer it has to be perfectly flat on both sides or it will cause the impeller to hit the liner.

I realize that much, Just wondering if there is something specific guys use to do it

unless you buy a complete motor with carbs assembled and run their timing, pipe, prop etc it will not be turn key. My buddy got one that was turn key, ran mint outta the box. I though you where running rich and needed to lean it out a bit, keep going with the carb tuning, you will get it dialed in soon enough.

I got it dialed in last night, everything but the impeller is xmetal, I doubt the prop changes jetting

xmetal is over rated not overly happy with my xmetal experience

do you think the 10/16 would be good for a stock 701? is it good for low end? im planning to get the prop and then gradually upgrade the motor with a b pipe and msd enhancer with an ada head. or would the 9/15 be better. i asked dave and he recommended the 10/16 for a stock motor but what about when i get into the mods. will the 10/16 still be a good impeller for low end hit?

NO, Use the 9/15

Last edited:

- Location

- South Florida

9/15 for stock for sure.

Good luck Munki. Im sure you are beyond frustrated at this point.

Im glad to hear xjcrawler's motor is performing well, though.

Good luck Munki. Im sure you are beyond frustrated at this point.

Im glad to hear xjcrawler's motor is performing well, though.

OCD Solutions

Original, Clean and Dependable Solutions

- Location

- Rentz, GA

Your results are not typical so there is likely something you are still overlooking but have been able to compensate for...for now. I will bet that you will have an answer within the next couple rides.

Are you feeling better about the power yet or does it still feel less than what you expected?

Are you feeling better about the power yet or does it still feel less than what you expected?

D-Roc

I forgot!

- Location

- Dirty River Rider

he said he got it dialed in last night so maybe he can tell us what he did. I would agree that the slight pitches of props won't need a jetting change. but i also don't pitch my prop to a motor persay. they do need to be matched but you don't get rid of a bog or hesitation with the pump. make the pump, pump. make the motor rip hard enough to almost overrev the pump. do some final tweaks to the pump to be sure its as good as it can be with the motor. i think your pump is working good and you gotta get your motor dialed in. but i have not rode your ski so i don't know for sure. I have my own thoughts on x-metal but they do not apply to your experience imo. I know what they can build, its power. once you get it working your going to be saying it was worth it and you will know more about how your ski needs to be setup for you to be happy with the x-metal parts you bought. when my buddy ordered his team scream motor years ago, they did not reccommend a prop, they just said to make sure you do something with your pump to make this motor work. he used the skat/tbm combo. It was a very impressive setup. I will also say that once his TL died and it had an enhancer in it, bla, my 735 hit better.

Your results are not typical so there is likely something you are still overlooking but have been able to compensate for...for now. I will bet that you will have an answer within the next couple rides.

Are you feeling better about the power yet or does it still feel less than what you expected?

Its still a little less then expected, I'm sure its the impeller I'm going to get the impeller Xmetal just recommended, I emailed them again last week and they told me a different pitch but, Ill try it anyways, I found it interesting that both Art and Chuck say the hooker is too far set-back for the smaller cc set-ups and in talking to both of them thats pretty much the only thing they both agree on.

xj/mcdogs motor was looked over by Art and he was adamant that the port timing was off and not as good as it should be but the best he could do, Comparing the two motors mine hits first but his hits quicker. Mine still feels a little flat I'm pretty positive its the impeller but Im going to play with the Epic and water screws on my pipe, when I was playing with my ported 701 I found the middle screw on the head pipe 1/2 turn out gave me the most punch not the bottom screw so if the weather is nice Im going to try that...

IceMan did a negative feedback a while back and his experiences almost doubled mine, I'm not overly happy with the entire xmetal experience...

D-Roc

I forgot!

- Location

- Dirty River Rider

hows your piston wash? does your motor rev up and seem to be running good? if your pistons are clean you are rich and it is going to run forever but not run pissed off like. if your motor is revving fast and always there, then look at your pump. you can still buy a tbm skat for your setup and sell off all those crappy other props you got. get the best. I can understand the TS expereince, they have their own issue with dealing with customers, but what about the parts? once you get the parts dialed in i think you would be happy. they build strong motors. for future reference i have used blowsion, AJS, Macc Racing, for the past 10 years of building and they always hook me up the way it should be.

Last edited:

I havent checked my piston wash but I'm 1/8 in on the top and 1/2 out on the bottom from xmetal recommendations 5/8 Out on the top and 1 7/8 bottom, Not sure if piston wash would have changed much, But Ill check at the end of the day

as per http://www.x-h2o.com/threads/39846-Tuning-tips-for-Rookies after 1 1/4 turns out I should bump it up a jet?

Xmetal Spec

112.5 High with 5/8 - 3/4 turn out

117.5 Low with 1 3/8 turn out

Actual

112.5 High 5/8 turn out

117.5 Low 1 7/8 turn out

But I was rich in the first place so a bigger jet doesn't make sense jugging by my first look at the pistons, So I think Ill wait and try the next impeller before I re-jet

as per http://www.x-h2o.com/threads/39846-Tuning-tips-for-Rookies after 1 1/4 turns out I should bump it up a jet?

Xmetal Spec

112.5 High with 5/8 - 3/4 turn out

117.5 Low with 1 3/8 turn out

Actual

112.5 High 5/8 turn out

117.5 Low 1 7/8 turn out

But I was rich in the first place so a bigger jet doesn't make sense jugging by my first look at the pistons, So I think Ill wait and try the next impeller before I re-jet

Last edited:

D-Roc

I forgot!

- Location

- Dirty River Rider

your rich, you need to turn the screws in, or go smaller jets. if you change your prop one more time i am buying a plane ticket.......

:wall: I changed the curve from the ATP to the Xmetal curve quite a noticeable difference for the better, I was planning on doing this earlier but I kinda misplaced the cable.

But it still has that slight hesitation when I pull the trigger, the motor sounds healthy, Closest thing I can compare it to is its like driving a standard car and your ridding the clutch a second to long before it engages...So I think Ill try a different um...impeller, Im going to have quite the collection of impellers after this summer, But Ive still got to wait for the strike to be over

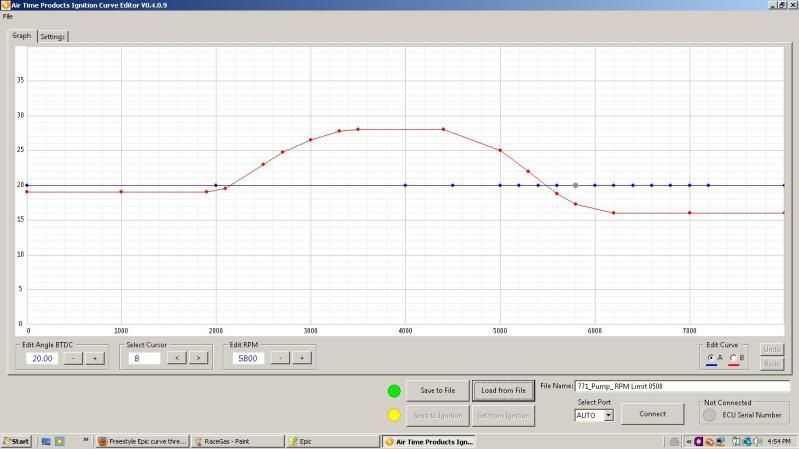

This is what i was running Curve A

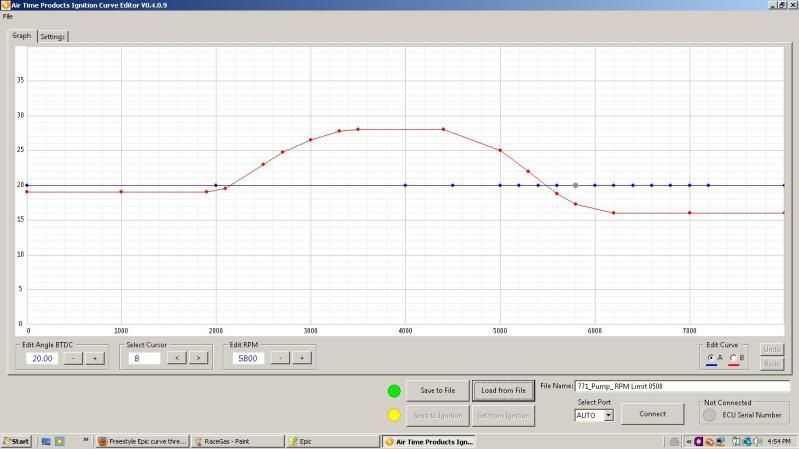

This is what im running now Curve B

But it still has that slight hesitation when I pull the trigger, the motor sounds healthy, Closest thing I can compare it to is its like driving a standard car and your ridding the clutch a second to long before it engages...So I think Ill try a different um...impeller, Im going to have quite the collection of impellers after this summer, But Ive still got to wait for the strike to be over

This is what i was running Curve A

This is what im running now Curve B

D-Roc

I forgot!

- Location

- Dirty River Rider

i had my solas not give good pump hookup. if the ski is moving and you punch it, the ski would respond nice but if you where moving too slow the motor would rev up and then hit. No prop will give you what the tbm or the blowsion pump stuffer cone does. I cannot understand what it would take to convince people of this. If your plugs and piston wash is not correct then you are still rich, your elevation may be the cause for this and turning the screws may not be enough. if it was my ski i would put in one size smaller jets and then set the screws at 1 and start the tuning process over. but again, i have not rode your ski to feel what it is doing. maybe your motor is tune as good as it will get. I also have a TL ignition which makes my ski what it is, without TL, my ski is as only as good as everyone elses i have rode. TL is the most bang you can get imo. i know its not in your budget this year but if you do plan on getting one down the road, why not get a prop/pump combo that will still work when you do? I sure hope you can get this setup to work, you have got way too much invested in props, is crazy, sorry but it is. I don't believe what a salesman of any type tells me, he is trying to sell you what he has. i always throw some BS into conversations to see how they respond. this lets me know what kind of person i am dealing with and if he is going to set the record straight or continue with my BS statement hoping to make a sale. your hooker prop will never work as good as a c-75 big hub prop combined with the Blowsion or TBM or R@D supercone. never. physically impossible. this is not a rant, i just get frustrated seeing people have their ride season and money wasted.

D-Roc

I forgot!

- Location

- Dirty River Rider

fyi, i run 32 degrees upto 5500 rpm and cut back to hit 17@7000 rpm with a 8500rpm rev limit. you are jetted rich and/or conservative with your timing.

OCD Solutions

Original, Clean and Dependable Solutions

- Location

- Rentz, GA

That "hesitation" is the last thing I was looking to get rid of in my wifes 07 SJ with the 10/16. I eventually purchased an 8 vane 140mm Mag pump with a C75 14/19 and that solved the hesitation. It really needs a 13/18 to get the snap back that the 10/16 had but its still worlds better.

Now, before you rush out to buy a Mag pump, there may be more to do with your pump first, especially if you are happy with the current pitch. I have been playing with my Mag pump and have simply added a single 2.5mm washer to space the impeller, and this has given me a hesitation. So, if spacing a prop in a mag can add hesitation, setting back and closing that gap on an OEM pump should remove it for the same reasons. I'm not sure how involved it would be to setback your own impeller but it would be worth a try if you knew someone with the tools to do it. The other option would be to take some measurements to your stator and get your current impeller setback as much as possible.

Shipping isn't cheap but neither is buying new impellers all the time.

Now, before you rush out to buy a Mag pump, there may be more to do with your pump first, especially if you are happy with the current pitch. I have been playing with my Mag pump and have simply added a single 2.5mm washer to space the impeller, and this has given me a hesitation. So, if spacing a prop in a mag can add hesitation, setting back and closing that gap on an OEM pump should remove it for the same reasons. I'm not sure how involved it would be to setback your own impeller but it would be worth a try if you knew someone with the tools to do it. The other option would be to take some measurements to your stator and get your current impeller setback as much as possible.

Shipping isn't cheap but neither is buying new impellers all the time.

D-Roc

I forgot!

- Location

- Dirty River Rider

i can agree with that and is why i push the tbm thing, you get some adjustability with it using one prop/pitch. I also got my blowsion reduction nozzle to accept 84mm-89mm rings so i can adjust my pump. a mag is even better yet for processing the water but its another big $ item, which i think can be benifitial on any ski so the sooner you get one the better. i just got my good carbs and the TL first and have been able to keep my tbm/skat to work amazing. we have tested my same setup with different reduction nozzle sizes on 701, 718, 735 771 and the 828 5 mm stroker. never had any hookup, hit, responce problems on any.