there was another small tiny batch of ADA heads / domes where the groove for the O ring had been machined too big, do a close visual inspection and make sure the O rings sit nice and snug and don't have play...

The girdle bolts we tighten to 35 , that is not recommend specs from ADA but instructions from some engine builders thus some of these head had been known to improperly seal with 25 ...actual head screws stay with ada recommended specs... ( Yamaha )

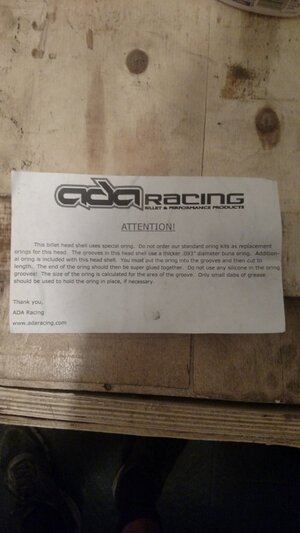

The oring where the dome meets the head seems to be very loose in the groove. I’m thinking that this may give the domes just enough play to pop an oring. Would getting a larger oring be a similar solution as shimming the domes?

Sent from my iPhone using Tapatalk