i love the clear conscise explanation and answers to the questions i had sent..by comparison i sent the same email to wamilton and received this confusing reply which doesnt address the question at all...guess who's getting my business.

here for your viewing pleasure is the exchange.. ill skip the first email detailing my problem and set up, the reply was to adjust my set screws in my b-pipe..here goes

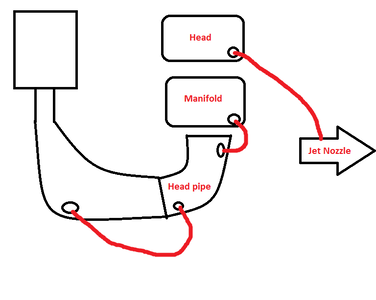

ME - [FONT="]your diagram and instruction to run as such are almost exactly how i have it in my ski currently, which i had listed in my original email.the only change is you go from top of head pipe to stinger with a 3/8 bypass and front cylinder head goes direct overboard.

mine is top of head to pisser, front cylinder head to bypass/stinger/overboard

as well as the settings on the b-pipe set screws, mine are identical.

this slight change in line routing in no way helps resolve the high flow of cold water through the engine nor does it address th need to raise operating engine temp.

what i need to do is keep the water in the cylinders longer to warm the engine temp as the water coming out both pissers is cold.

hence my question about restricting the flow coming out of the head.

hope this clarifies things a bit.

TO WHICH I GOT THIS REPLY -

[/FONT][FONT="]You thinking too hard, in reality you will not benefit from the change you want to do, your water temperature will go up in the near future, plus your ski gets hot on the manifold plate that is inefficient due to the restrictions due to the original design from the factory. [/FONT]

UHMM..OK.. so not even remotely close to the topic..not to mention the water temp will go up eventually comment..ya..sure it will..here in central western canada that should be..oh...when the polar ice cap melts..

i feel almost as if this was some bot replying without ever addressing the legitimate question..such a huge contrast from the professionalism over at jetworks.