You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom/Hybrid Backi-Chan build

- Thread starter d_moss

- Start date

swapmeet

Brotastic

- Location

- Arlington TX

Well, sorta. This was taken when I was making. Turf 'foot' for my box to keep it from rolling.

This was before I had the chamber in. Once I had the chamber in I had to move the WB back to where the knots in the straps were in front of the box. It was about half way up.

This was before I had the chamber in. Once I had the chamber in I had to move the WB back to where the knots in the straps were in front of the box. It was about half way up.

- Location

- Rexburg, ID

Yami-Rider

TigerCraft FV-PRO

- Location

- Texoma

Oh and either remove your alignment pins our drill holes in the hull for the pump and the mid shaft. I drilled holes and that was a pain. If you are not perfect you throw everyting off.

IMO you should remove dowel pins, im not sure how you would drill the holes in the correct place.

Pump alingment: Tape your drive shaft with painters tape till it fit tightly in the threw hull pvc pipe, this will make your driveline dead center, then add the correct amount of shims. I used small SS shims from mcmaster, they are cheaper them oem.

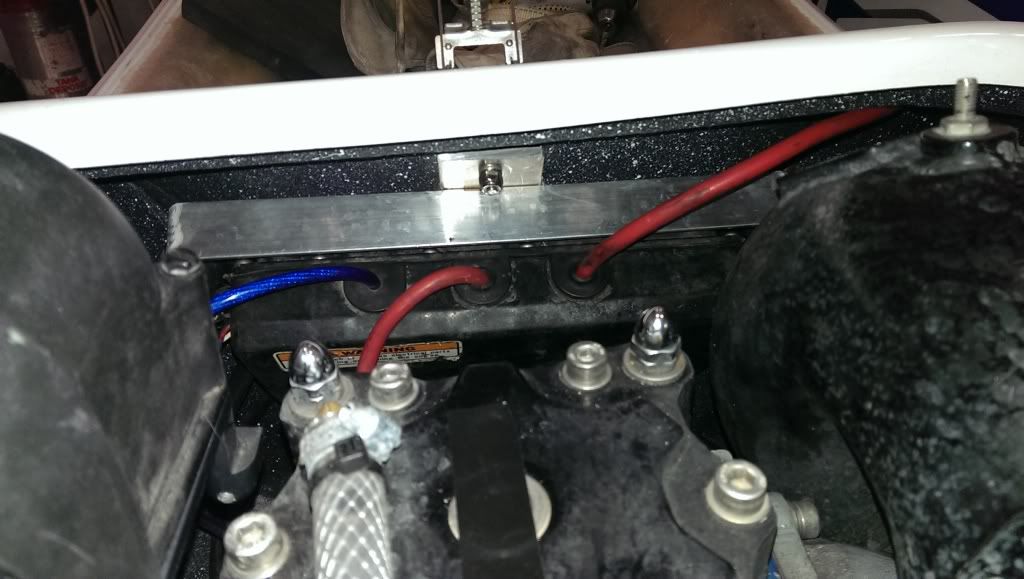

Good work on your ebox mount..now you just need to paint it black :bigok:.

- Location

- amarillo ,tx

What pvc tube isnt one

NO WHITE FLAGS

DONT GIVE UP DONT SURRENDER

NO WHITE FLAGS

DONT GIVE UP DONT SURRENDER

swapmeet

Brotastic

- Location

- Arlington TX

What pvc tube isnt one

I guess you're there with the owner?

Click this, and then the zoom in button on the bottom right of the picture.

http://s194.photobucket.com/user/danyz250f/media/IMAG0253_zpsf70a6fff.jpg.html

Last edited:

- Location

- amarillo ,tx

Lmao oh hell i c it now, pic is awfully deceiving. Even on computer

NO WHITE FLAGS

DONT GIVE UP DONT SURRENDER

NO WHITE FLAGS

DONT GIVE UP DONT SURRENDER

- Location

- Cruising Around

I've done that a few times and it still looks like just a hole through the bottom deck, that's why I asked twice. Swap, you see a tube in there? Edit: I got bad eyes or bad screen. Well hope all goes well, really like the white.

Last edited:

swapmeet

Brotastic

- Location

- Arlington TX

I'll admit that that one pic makes it really hard to believe that a tube is in there. But I kinda fall back on common sense, and then looked closely at the pic to confirm.... Steve wouldn't ship a ski without a tube.

But yes.... lol I had to look twice.

But yes.... lol I had to look twice.

sjetrider

615 Freeriders are addicted to T1 madness.

- Location

- in the 615 (Nashville)

IMO you should remove dowel pins, im not sure how you would drill the holes in the correct place.

Pump alingment: Tape your drive shaft with painters tape till it fit tightly in the threw hull pvc pipe, this will make your driveline dead center, then add the correct amount of shims. I used small SS shims from mcmaster, they are cheaper them oem.

Good work on your ebox mount..now you just need to paint it black :bigok:.

Tape your drive shaft with painters tape till it fit tightly in the threw hull pvc pipeI strongly recomend you do not do the above. The proper way to allign your pump is to : Remove midshaft from housing, bolt midshaft housing w/o midshaft into place on bulkhead. Then line your pump up to the center of the hole in the midshaft housing. DO NOT LINE YOUR PUMP UP TO THE HOLE IN THE BULKHEAD, it is not always correct or center. Use the midshaft as this is what your motor will line up to.

sjetrider

615 Freeriders are addicted to T1 madness.

- Location

- in the 615 (Nashville)

my opinion on the ebox mount is use OEM mounts and bolt them through the bulkhead like OEM, use counter sunk allen heads on outside and turf over them or just leave them its a small pattern and look fine countersunk from outside. Its a part you will not likely ever have to remove.

Not much to not like about these hulls, the designs seem to be great and purposefull and they look noce and appear to be well made. Nice purchase bro!

Not much to not like about these hulls, the designs seem to be great and purposefull and they look noce and appear to be well made. Nice purchase bro!

swapmeet

Brotastic

- Location

- Arlington TX

Ebox mounting is more difficult than stock because the firewall is curved instead of flat. Not a huge issue, but to a first timer it can make you go 'wtf?'

On the pump alignment, one trick I learned (not sure it really qualifies as a trick...) But I mounted the pump so the drive shaft comes through, but loosely, then slid the midshaft and housing over the driveshaft and let it 'float'. Then I adjust the pump so the mounting holes on the midshaft housing line up with related threaded inserts in the bulk head. Once lined up, I lock down the pump, bolt the housing in place and move on to the engine.

Hope that makes sense.

On the pump alignment, one trick I learned (not sure it really qualifies as a trick...) But I mounted the pump so the drive shaft comes through, but loosely, then slid the midshaft and housing over the driveshaft and let it 'float'. Then I adjust the pump so the mounting holes on the midshaft housing line up with related threaded inserts in the bulk head. Once lined up, I lock down the pump, bolt the housing in place and move on to the engine.

Hope that makes sense.

Last edited:

iangdesign

Cats, lots of cats!

- Location

- United States

I def like the white of the hull...it's a blank canvas so you can make it whatever you want. I have seen some sweet paint jobs on the Chans, but non really my style. Are you going to do a vinyl wrap on the hull or just leave it white?

Thanks for the honesty in your build thread as well. Makes me appreciate Chans and the builder a little more. I am looking forward to seeing some of these hulls this weekend at WFs!

Thanks for the honesty in your build thread as well. Makes me appreciate Chans and the builder a little more. I am looking forward to seeing some of these hulls this weekend at WFs!

iangdesign

Cats, lots of cats!

- Location

- United States

Swap...I like your solution for the ebox mount. Very resourceful. Did you put any padding on the backside or anything to keep it from flexing side to side...or has that even been an issue?

swapmeet

Brotastic

- Location

- Arlington TX

Swap...I like your solution for the ebox mount. Very resourceful. Did you put any padding on the backside or anything to keep it from flexing side to side...or has that even been an issue?

Thanks! The plate isn't touching the firewall, so no need for padding. And the dimple stamps make it super rigid, it would take lots torque to make it flex.

Yami-Rider

TigerCraft FV-PRO

- Location

- Texoma

Tape your drive shaft with painters tape till it fit tightly in the threw hull pvc pipeI strongly recomend you do not do the above. The proper way to allign your pump is to : Remove midshaft from housing, bolt midshaft housing w/o midshaft into place on bulkhead. Then line your pump up to the center of the hole in the midshaft housing. DO NOT LINE YOUR PUMP UP TO THE HOLE IN THE BULKHEAD, it is not always correct or center. Use the midshaft as this is what your motor will line up to.

That is also a good idea, but if the ski was built correctly the pvc pipe should be dead center of the 3 bolt holes.

Taylor Curtis (TCfreeride) assembles all his rickter this way and is also how i assembled my buddies XFS with great success.

Bobert540

Site Supporter

- Location

- Rockford,MI

Ebox mounting is more difficult than stock because the firewall is curved instead of flat. Not a huge issue, but to a first timer it can make you go 'wtf?'

On the pump alignment, one trick I learned (not sure it really qualifies as a trick...) But I mounted the pump so the drive shaft comes through, but loosely, then slid the midshaft and housing over the driveshaft and let it 'float'. Then I adjust the pump so the mounting holes on the midshaft housing line up with related threaded inserts in the bulk head. Once lined up, I lock down the pump, bolt the housing in place and move on to the engine.

Hope that makes sense.

That's what I did and it seemed to make the most sense to me and it shouldn't cause any issues.

if you mount the pump first and try to align it with the center of the tube then put the midshaft on, there will be stress on the midshaft/driveshaft splines that will cause premature wear.

sjetrider

615 Freeriders are addicted to T1 madness.

- Location

- in the 615 (Nashville)

That is also a good idea, but if the ski was built correctly the pvc pipe should be dead center of the 3 bolt holes.

Taylor Curtis (TCfreeride) assembles all his rickter this way and is also how i assembled my buddies XFS with great success.

Maybe Rickters are perfect although OEM and most I have built were not.

- Location

- Rexburg, ID

I want to see if I can get some stickers similar to the 14 sj. I think they are simple and sweet

Sent from my HTC One using Forum Fiend v1.0.1.

Sent from my HTC One using Forum Fiend v1.0.1.

- Location

- Spokane,wa

it so pretty,i wish i save up my penny for a chan,but now i am putting my money into a motor and if i knew more about motor back then with we traded i would have store it...lol...but i met a guy at surf slam with a chan and he had a 550 tank on his hull.it look pretty sweet the way he had it set up....i wish i had taken some picture of his set up...so now with the new hull i guess corbin park will not be a riding spot....lol....