- Location

- NH

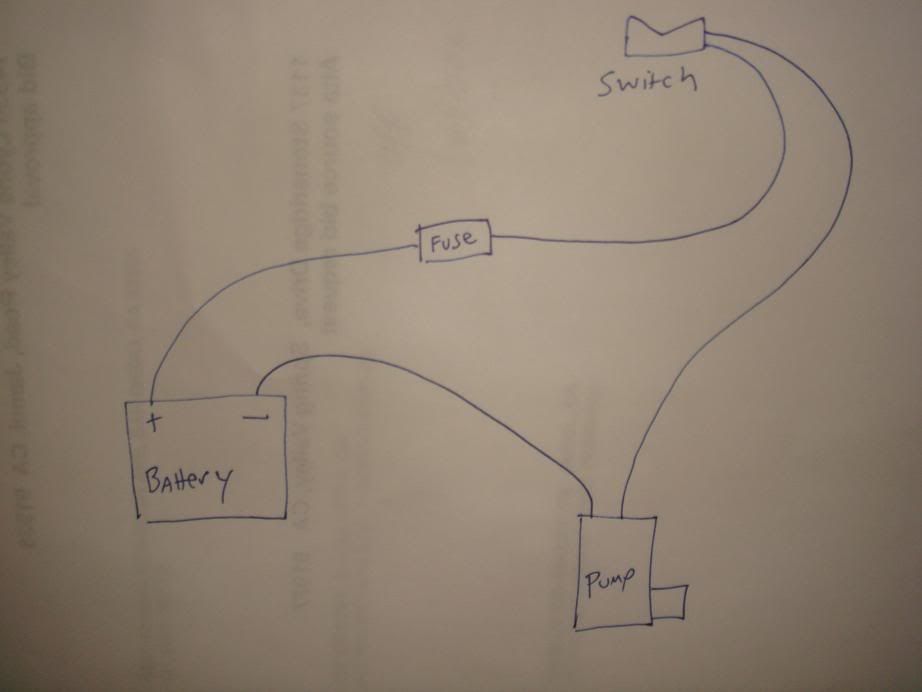

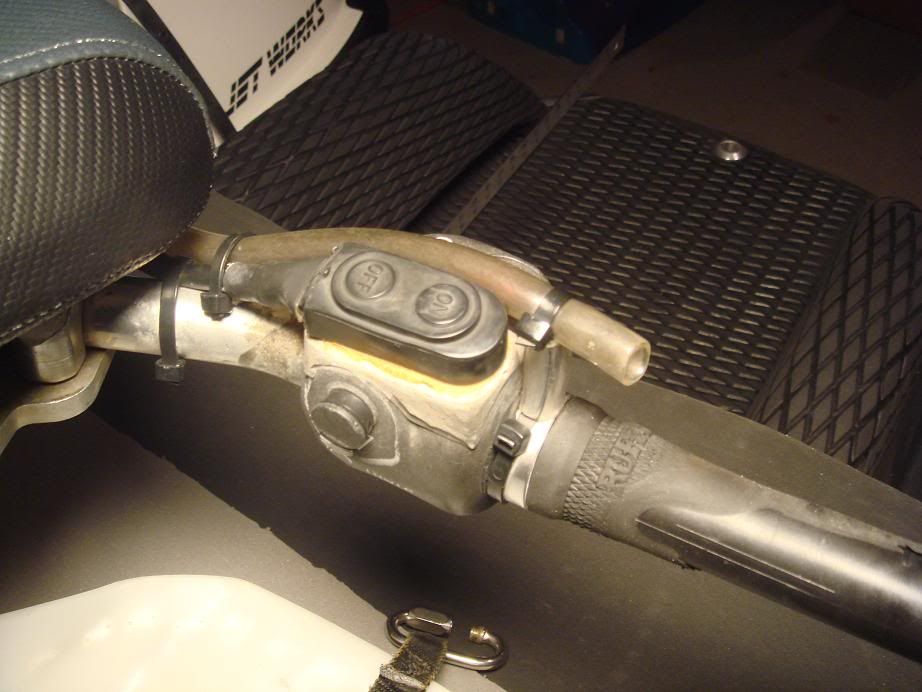

I have a rule 500 GPH in my 750 SXI. I had the ski down to the hull to do repairs and paint. Since I have put it back together I have burned up two toggle switches for the bilge pump. I had a switch wired up the exact same way last year but I replaced in because it was rusty(still worked though). Both switches I wrecked were heavy duty waterproof and different manufactures. I have it wired directly to the battery with all connections soldered and heat shrinked. Any ideas?

Will

Will