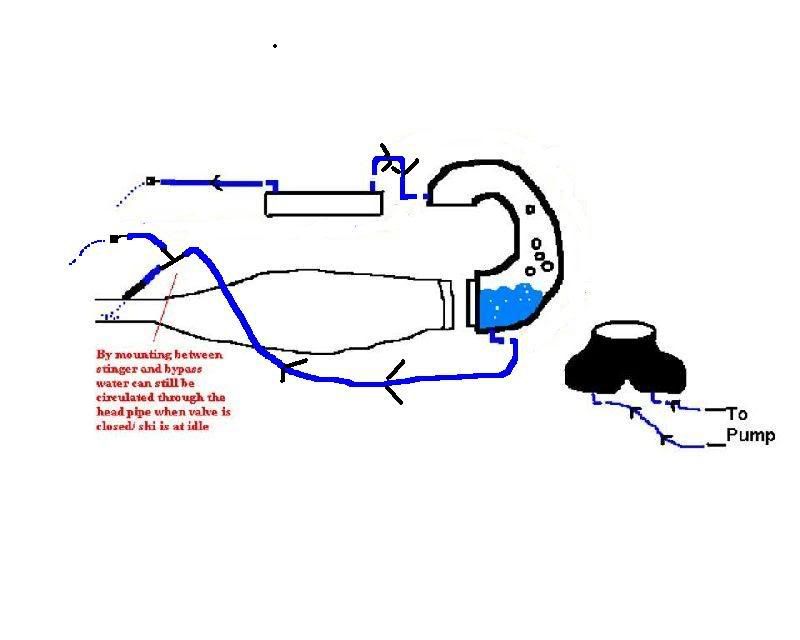

these type billet motors with 4 outlets for cooling can be more difficult to tune with a bpipe, its a balancing act, the billet cylinder needs more outlets to keep cylinder temps under control,creating a high flow rate,but low pressure state in the entire system.The bpipe relies on water pressure through the whole head pipe to cool it and inject water into the pipe to control pipe temp. With this cylinder,water temps going to the head pipe is already hotter than most,requiring even more water pressure to hit the correct pipe temp for low end response. Not difficult to do in cold spring,fall water temps,but tough in dog day summer water. Try to temp block off the 2 extra high flow rate pissers and see what kinda pipe response you get,vs motor temps. then use restrictions in those 2 lines to find the best balance.

The rrp wetpipe and pfp when used as wet pipe.use a dedicated injection line separate of the manifold cooling water,the T fitting is placed in front of the manifold cooling fitting so pressure is very high in any kind of motor cooling setup,the only disadvantage in that all sand or solids passing through the line have to be filtered as not to clog the jet.Ive thought of trying to drill the rrp mani and tap it where the cooling jacket is for the jet and a plug on outside,solids would bypass the jet as they do in the bpipe. more trouble than its worth really