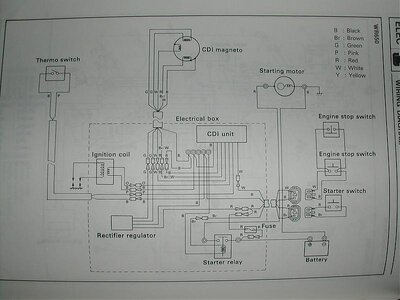

in that diagram, the CDI unit, is connected to the rectified output of the regulator/recitifiar.

and the other two coils are connected to the CDI unit too.

do you think it takes in that AC from the charge coil and then rectifies it into DC to bump the ignition coil?

I really doubt it, most modern CDI unit charge the coil with AC voltage.

either way...

my initial point was, there isnt 20-60 Volts DC coming anywhere from a superjet stator.

My guess is in the manual he read the OPEN CIRCUIT voltage of the battery charging circuit ( DC side of the rectifier), instead of the cdi charging circuit.

the battery holds the voltage down to 15 volts or whatever.. open circuit MIght be as much as 60 volts DC

I only point that out for folks that are trouble shooting in the future, its hard enough to find info on these things.

"Charging the coil" is a multi-step process.

If I remember correctly, it gets doubled once, then put through a diode network (to get rectified), then into a transformer.

The secondary of that tx feeds the coil.

It is a bit more complex than that, but that's the basics.

EDIT: 12VDC is for charging the battery, nothing else.