You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Freestyle ET 967 Setup?

- Thread starter Citizen

- Start date

Yami-Rider

TigerCraft FV-PRO

- Location

- Texoma

Impros 11/17 148?, surpriced it can pull it. The ET's do have alot of bottom.

Just4Fun

First World Problems...

- Location

- Southern Oregon

Impros 11/17 148?, surpriced it can pull it. The ET's do have alot of bottom.

They dont have a lot of bottom ive seen videos of 967's idle flippng lol??

My surf ski is haz a 967 litterally everyone who rode it at pac city freeride said i wish my ski had bottom like that. those motors are versatile if you rode one that isnt pulling youre arms off bottom to top then it wasnt setup right. at keast thats my experience with my 967...

Just4Fun

First World Problems...

- Location

- Southern Oregon

My 967 is setup in a sv1

Enhancer

Lightened flywheel

Tnt v3

Php mani

Vf3s

Stock 46's

135 pilot 3/8th - 1/2 turn

130 main 1/2 turn

95g 21 psi synced

148 torrrent

Skat Prop is 9/18 ish i bent myself

86mm reduction nozzle

92mm steering nozzle

Stub cone

If you are looking for more bottom you might try opening up yhe reduction nozzle to 87 then 88 etc until you find the power to youre liking.

i have held wide open for ten seconds multiple times a little to fast for my liking, lol

Enhancer

Lightened flywheel

Tnt v3

Php mani

Vf3s

Stock 46's

135 pilot 3/8th - 1/2 turn

130 main 1/2 turn

95g 21 psi synced

148 torrrent

Skat Prop is 9/18 ish i bent myself

86mm reduction nozzle

92mm steering nozzle

Stub cone

If you are looking for more bottom you might try opening up yhe reduction nozzle to 87 then 88 etc until you find the power to youre liking.

i have held wide open for ten seconds multiple times a little to fast for my liking, lol

Yami-Rider

TigerCraft FV-PRO

- Location

- Texoma

Yami-Rider

TigerCraft FV-PRO

- Location

- Texoma

Your prop is about what I was thinking. A 13/18 seems a bit much.

He has a 9/15 Impros, which is around a 10/16 skat maybe more, I know Impros Hooker numbers are lower then their actual pitch.

He has a 9/15 Impros, which is around a 10/16 skat maybe more, I know Impros Hooker numbers are lower then their actual pitch.

- Location

- Coeur D' Alene, ID

So i double checked and it is a 9/15 skat trac, not a Impros. The hooker was on my old ski apparently. Thanks for all the feedback so far guys.

Proformance1

Liquid Insanity

- Location

- New York Crew

Impros sells Skat so it still could be an Impros modified Skat prop. They make sure the angles are prefect, balance them and do extras if required/asked for. Cut backs, extra cuts, welds, repitch, etc.

- Location

- Coeur D' Alene, ID

Will definitely update this with ride reports and tuning. Should be here Tuesday, i hope to hit the water Wednesday to start break in.

- Location

- Coeur D' Alene, ID

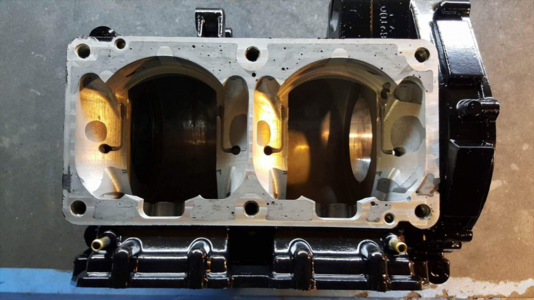

Motor showed up today, showed up well packaged with no damage. I agreed to have him use used cases to cut down on build time instead of waiting on OEM to show up but I am a little concerned about the gray epoxy in the stator area. Was this case cracked at some point and repaired?

Attachments

DAG

Yes, my balls tickled from that landing

- Location

- Charlotte, NC

Dig the epoxy out and find out lol

- Location

- Valley Springs, CA

No it was not lol, you see when you try to stuff larger sleeves in cases designed for 701/760 displacement. You have to make room for them, what your seeing is epoxy. But it was not damaged at one time, it was added as a strengthener/filler material so that Art could hog the cases out for proper sleeve clearance/porting. Perfectly normal

- Location

- Coeur D' Alene, ID

No it was not lol, you see when you try to stuff larger sleeves in cases designed for 701/760 displacement. You have to make room for them, what your seeing is epoxy. But it was not damaged at one time, it was added as a strengthener/filler material so that Art could hog the cases out for proper sleeve clearance/porting. Perfectly normal

Awesome man thank you for the explanation!

Just4Fun

First World Problems...

- Location

- Southern Oregon

My 967 looked the same nothing to worry about..

Yami-Rider

TigerCraft FV-PRO

- Location

- Texoma

All big bore motors are like that, even my JetManiac 781 was.

Yami-Rider

TigerCraft FV-PRO

- Location

- Texoma

- Location

- Coeur D' Alene, ID

Ok, next issue!

First time with a powervalve motor so I am discovering that B pipes are a huge pain in the ass with these. I couldn't find a good guide for grinding the B pipe head to clear the valves other than "grind till it fits and epoxy/weld if you break into water jacket". Does anyone have pictures of a properly modified pipe?

Welding will be an issue for me but i can epoxy it if needed. My main question is this:

Will grinding the pipe to work with power valves effect the performance and resale of the pipe? I am only planning on using the bpipe for about a month before I buy a power factor, so if I cut up my bpipe and then can't sell it for the $600-650 I am expecting I might hold off till I can just get the PFP.

First time with a powervalve motor so I am discovering that B pipes are a huge pain in the ass with these. I couldn't find a good guide for grinding the B pipe head to clear the valves other than "grind till it fits and epoxy/weld if you break into water jacket". Does anyone have pictures of a properly modified pipe?

Welding will be an issue for me but i can epoxy it if needed. My main question is this:

Will grinding the pipe to work with power valves effect the performance and resale of the pipe? I am only planning on using the bpipe for about a month before I buy a power factor, so if I cut up my bpipe and then can't sell it for the $600-650 I am expecting I might hold off till I can just get the PFP.

- Location

- North Carolina

Whether or not it would affect the price is for the buyer to decide. Some people might pay more while others would find it less desirable. It will not affect the performance however I would rather it be welded that epoxy.