I have been sanding and filling my ass off, IT SUCKS. In the mean time I got good news from my uncle. I will be getting free paint, primer, and use of a spray booth when ever I need it. The ski will be gunmetal grey. I also began installing footholds I got from Tom21. I have a front foothold on the way this week as well. I think I will get alot of use out of it because after mocking up my pole and standing in the footholds I cant believe how much further you have to lean with a -4 pole. It is going to take some time to get acclimated with for sure.

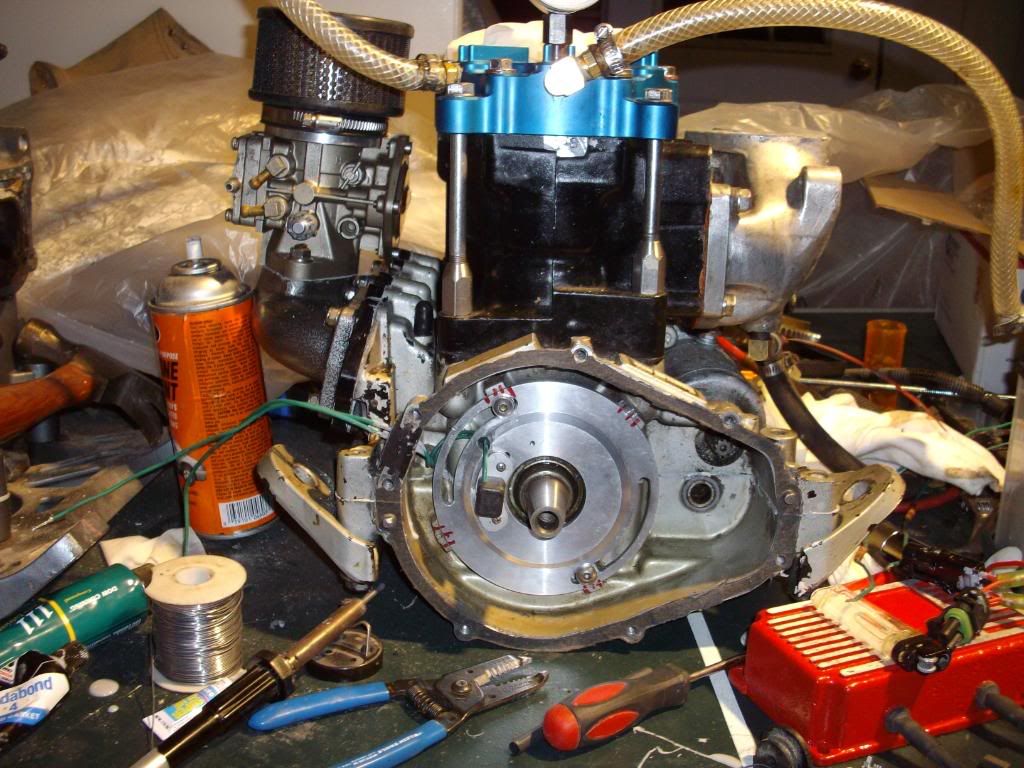

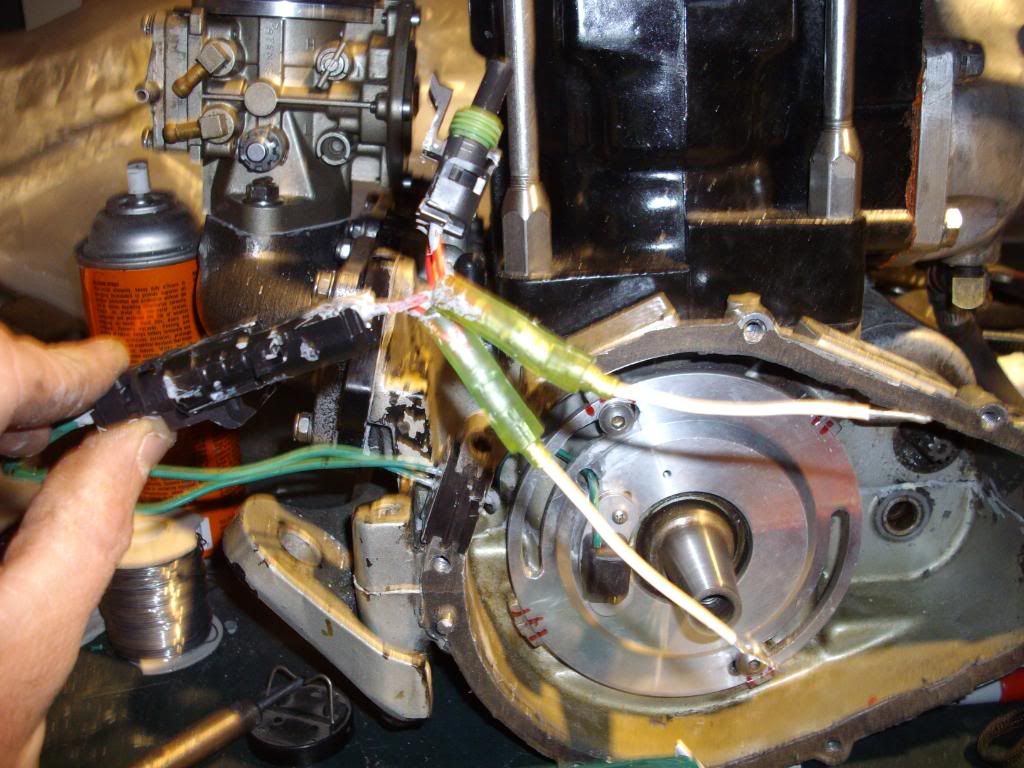

Motor update: I went ahead and spent some $$$ on a tl system and jetworks battery.

I will also be running a 48mm full spec, so I am expecting a very noticeable difference in my motor this season.

Hopefully this week I can be finished with all the footholds, sanding and filling the hood and nose, and mocking up something for my rn waterbox to run a front exhaust... I need to get the rag out of my ass and get finished soon, Its getting warm quickly