Vumad

Super Hero, with a cape!

- Location

- St. Pete, FL

I have a few ideas for building an X2. The modifications I am talking about concern the hull only at this time. Here's what I have in mind.

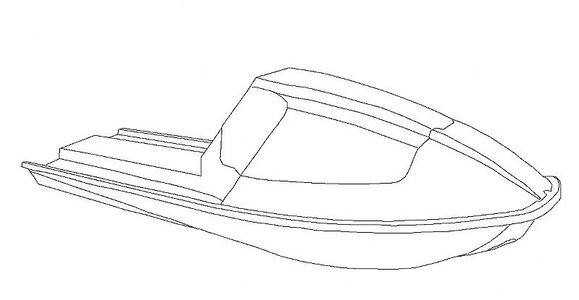

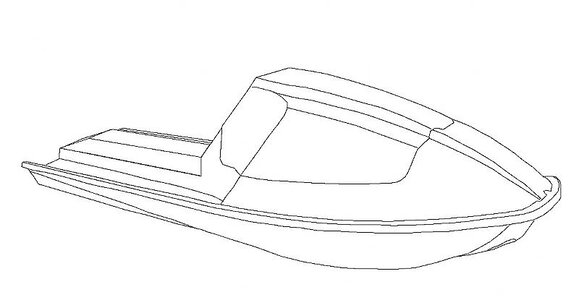

- Completely redesigned hood. Hood taking after the Stand up/new X2 design.

- Shaved fuel fill. Keeping external fill, but modifying the nose for a cleaner look and no fuel door.

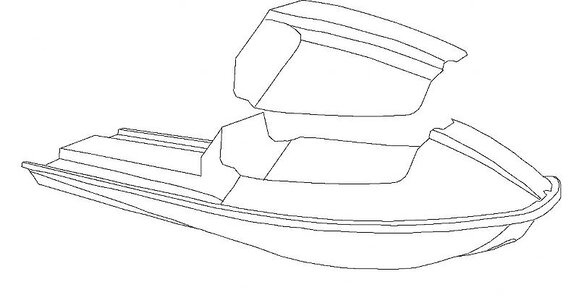

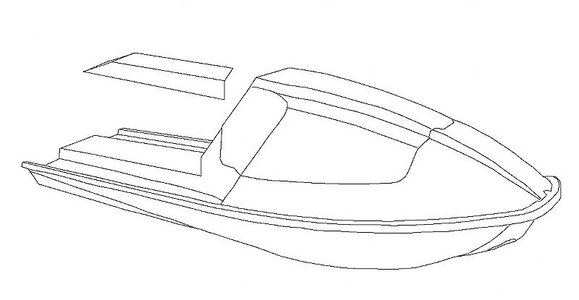

- Custom tray. idea is to chop the seat down to the lowest possible point (can't cut it flat because of the pump). Make removeable trays to fit into the current foot wells, and a removable seat. The ski would be set up to be convertable b/t a flat deck and a normal X2 seating position. Recessed hood latches would hold these parts in place. Fire extinguisher and dry compartment will be worked into the seat.

- Tubbies w/ exhaust outlet moved up to waterbox

- Possibly a hull modification like what Crab's build

- Possibly shorten the hull a currently undecided amount for carving and surf slashing

Things to take into consideration...

- A custom hood bracket will have to be made.

- E-box would be mounted on the back wall of the engine compartment, cables will be moved to the bottom using longer stand up cables freeing up this real estate

- possibly upgrading to 6 gallon high capacity fuel tank after E-box has been moved

- 750 twin carb with stock air box, stock waterbox, westcoast pipe, stock electronics

- Need to determine locations for things like bilge outlets, bilge switch, primer valve, fuel toggle, etc.

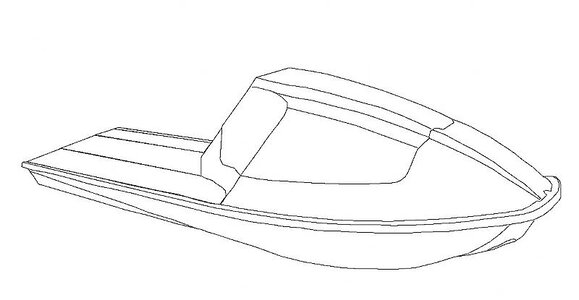

The attached picture shows the idea for the hood modification. The picture also shows the chopped tray, but it does not show the removeable parts of the tray yet. Fuel cap mod is not shown.

Edit: Added sketches of seat both attached and removed and a pic with the tray inserts. Clips not shown.

Input!!! What do you think?

Thanks

PS. Images are to scale. What scale? I dunno, but they are proportionate.

- Completely redesigned hood. Hood taking after the Stand up/new X2 design.

- Shaved fuel fill. Keeping external fill, but modifying the nose for a cleaner look and no fuel door.

- Custom tray. idea is to chop the seat down to the lowest possible point (can't cut it flat because of the pump). Make removeable trays to fit into the current foot wells, and a removable seat. The ski would be set up to be convertable b/t a flat deck and a normal X2 seating position. Recessed hood latches would hold these parts in place. Fire extinguisher and dry compartment will be worked into the seat.

- Tubbies w/ exhaust outlet moved up to waterbox

- Possibly a hull modification like what Crab's build

- Possibly shorten the hull a currently undecided amount for carving and surf slashing

Things to take into consideration...

- A custom hood bracket will have to be made.

- E-box would be mounted on the back wall of the engine compartment, cables will be moved to the bottom using longer stand up cables freeing up this real estate

- possibly upgrading to 6 gallon high capacity fuel tank after E-box has been moved

- 750 twin carb with stock air box, stock waterbox, westcoast pipe, stock electronics

- Need to determine locations for things like bilge outlets, bilge switch, primer valve, fuel toggle, etc.

The attached picture shows the idea for the hood modification. The picture also shows the chopped tray, but it does not show the removeable parts of the tray yet. Fuel cap mod is not shown.

Edit: Added sketches of seat both attached and removed and a pic with the tray inserts. Clips not shown.

Input!!! What do you think?

Thanks

PS. Images are to scale. What scale? I dunno, but they are proportionate.

Attachments

Last edited: