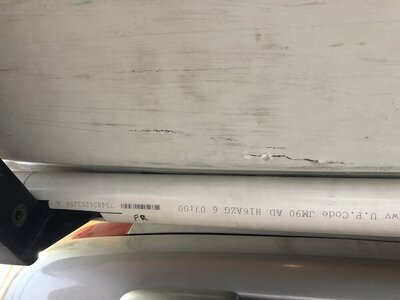

Next came the crack on the bottom that I thought would be just a simple V notch with the dremel. Was grinding at it and could tell the whole area was delaminating. Turns out there must've been a deep gouge that was painted over and then epoxy filled. Kept using a small screw driver to try to peel at the edges to see if it's poorly adhered. Ended up with this huge area that I hit with a 2" 60 grit flap disc on the die grinder to get down to SMC. Feathered the edges nicely with that then used various layers of the 8.5oz twill depending on the depth in that area. 5 layers everywhere and another 2-3 to get it flat.

You can see where the idiots just put thickened epoxy over paint.

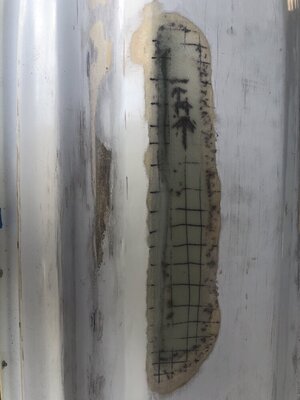

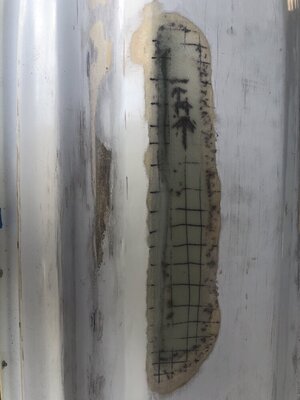

Let it dry then hit it with the orbital and 60 grit to knock down the high spots. Used a grid of sharpie lines as a redneck guide coat to find the lows.

Then a few more layers of cloth in the low spots. I'd much rather add glass than just thickened epoxy. Once this dried it was sanded and just a skim coat of thickened epoxy over top. This way I didn't need but just 1/16" of filler in the lows and nothing in most the area.

After sanding this just a skim coat of glazing putty to fill the pinholes. Decided to repaint most of the bottom. Used the leftover epoxy primer and paint from before. I didn't want to mess with the spray gun so I went with a couple $5 Preval sprayers. It's like a refillable rattle can, but it also sprays like one. Plenty good however for small areas like this, especially the bottom. Same process as before, wetsand the next day with 400 and 600 then paint. Then 1k, 2k, 3k, buff on the paint. I haven't done much paint blending, or paint at all for that matter, but I'm pretty happy with it. I curled the edges of the masking tape back and sprayed at an angle so it leaves a feathered edge instead of a hard one.

Took about 2 weeks out of the summer but I grinded to get it done before the 4th. Hopefully it holds, but only time will tell. At this point all the previous repairs are gone, so if it gives it's on me lol. Definitely not planning on buying any more skis with previous glass work. Will report back here if anything comes up or if I finally get (or build) a bigger motor for it.