You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The Circus

- Thread starter Sanoman

- Start date

The ski nautique (89) I've had for a couple years now l got of storage yesterday.Looks like l'm gonna work on it for a few weeks as it needs to be finished.Yes,l have screwed around too long with this project but since l can't ride this is a perfect time for it to be finished.And needed a break from my circus routine.

I cleaned and sanded the "bilge" area (below the engine) getting ready for paint today.Then the engine can be reinstalled later this week.The "waterbox",muffler what ever you want to call it has two intake areas where the exhaust manifolds clamp on to was basically burnt practically off so l ended up wrapping them with some 2" carbon tape.May need to do some more to make them stronger.Also found a leak on one side of this contraption and fixed it too.Then on to restoring the teak platform and trim that is on the inside of the gunnels that is used for stepping in the boat.That is a two step procedure for those who have not worked with teak before.Part A is for cleaning and bleaching,part B is for neutralizing your first step.Let dry for a few days and start laying the teak oil to it.

When l get it back from getting the engine back in the carpet goes down and then the seats.All the upholstery is done except for the engine cover.The exterior has been wet sanded and buffed already,so then l need to restripe and put the graphics back on.Other then touch up's the boat should be ready for a shakedown cruise.l also bought all the original decals for the trailer.But it needs to be sanded and repainted beforehand.My main intention was to keep it as close to original as possible.

I cleaned and sanded the "bilge" area (below the engine) getting ready for paint today.Then the engine can be reinstalled later this week.The "waterbox",muffler what ever you want to call it has two intake areas where the exhaust manifolds clamp on to was basically burnt practically off so l ended up wrapping them with some 2" carbon tape.May need to do some more to make them stronger.Also found a leak on one side of this contraption and fixed it too.Then on to restoring the teak platform and trim that is on the inside of the gunnels that is used for stepping in the boat.That is a two step procedure for those who have not worked with teak before.Part A is for cleaning and bleaching,part B is for neutralizing your first step.Let dry for a few days and start laying the teak oil to it.

When l get it back from getting the engine back in the carpet goes down and then the seats.All the upholstery is done except for the engine cover.The exterior has been wet sanded and buffed already,so then l need to restripe and put the graphics back on.Other then touch up's the boat should be ready for a shakedown cruise.l also bought all the original decals for the trailer.But it needs to be sanded and repainted beforehand.My main intention was to keep it as close to original as possible.

Attachments

Got done what l wanted to today.Long ass day though.Bilge area painted,teak cleaned,and ran to Walmart for a set of submersible lights.Got those installed,but still need to go back and replace the side marker lights.I won't do that till the trailer is painted.

Teak pics show before,freshly cleaned but still wet,and dry.Big difference! Just need to wait a couple days for the platform to dry out.Then l can lay the teak oil to it.

Teak pics show before,freshly cleaned but still wet,and dry.Big difference! Just need to wait a couple days for the platform to dry out.Then l can lay the teak oil to it.

Attachments

Ski boat is gone for engine install,hopefully not too long.So back on the Circus!

Yesterday afternoon l taped off the bond rail and cut all the excess off.That was a pita! This morning l sanded down the edges smooth.l have one area l want to work on a little more,but that's more finish work for later.l also filled the bond area inside in the engine bay in prep for laying 2" carbon tape.This bitch ain't coming apart.

All done for today.l'm beat..

Yesterday afternoon l taped off the bond rail and cut all the excess off.That was a pita! This morning l sanded down the edges smooth.l have one area l want to work on a little more,but that's more finish work for later.l also filled the bond area inside in the engine bay in prep for laying 2" carbon tape.This bitch ain't coming apart.

All done for today.l'm beat..

Attachments

My wife has been gone this week to her sisters so gave me time to get more done on the ski.Got the footholds done,so now at least the hull is ready to go to my painter.

Started last night preping and sanding all the areas that would ( 90° and a tyvek suit always feels awesome!) get epoxy and carbon tape.This morning l mixed up a small batch of thickened epoxy for all the screw holes l made on the holds and fill in some voids in different areas that got covered with carbon. l measured and cut 3" carbon tape for all the areas,then mixed up 9oz of epoxy.l always mark up each piece so no confusion during the process cause with it so hot,epoxy flash's quick.Wet all the pieces out and then layed it all out.It all worked out great.

Spent some time fitting the hood skin and liner together but it got too hot in my shop.Time for a beer..

Started last night preping and sanding all the areas that would ( 90° and a tyvek suit always feels awesome!) get epoxy and carbon tape.This morning l mixed up a small batch of thickened epoxy for all the screw holes l made on the holds and fill in some voids in different areas that got covered with carbon. l measured and cut 3" carbon tape for all the areas,then mixed up 9oz of epoxy.l always mark up each piece so no confusion during the process cause with it so hot,epoxy flash's quick.Wet all the pieces out and then layed it all out.It all worked out great.

Spent some time fitting the hood skin and liner together but it got too hot in my shop.Time for a beer..

Attachments

Last edited:

Painter? I hope it's clear you're putting on that beauty!My wife has been gone this week to her sisters so gave me time to get more done on the ski.Got the footholds done,so now at least the hull is ready to go to my painter.

Started last night preping and sanding all the areas that would ( 90° and a tyvek suit always feels awesome!) get epoxy and carbon tape.This morning l mixed up a small batch of thickened epoxy for all the screw holes l made on the holds and fill in some voids in different areas that got covered with carbon. l measured and cut 3" carbon tape for all the areas,then mixed up 9oz of epoxy.l always mark up each piece so no confusion during the process cause with it so hot,epoxy flash's quick.Wet all the pieces out and then layed it all out.It all worked out great.

Spent some time fitting the hood skin and liner together but it got too hot in my shop.Time for a beer..

YES!Painter? I hope it's clear you're putting on that beauty!

Started out great yesterday! Bike ride at 630 am,farmers market with the wife,2 grocery stores,then finally it was Circus time.Good day to work as far as temperatures go.

I cut the hand holds out and air vents in the back of the hood,sanded down,but still need some finish work.One of the things l have always wanted to do was make the inside of the rear vents look finished.l took a couple of pieces of carbon,prepped the liner and epoxied them down.

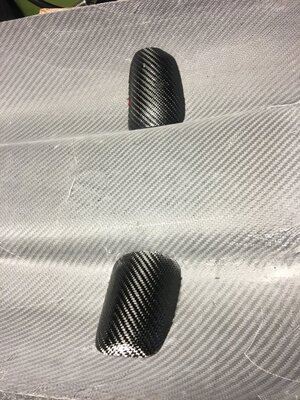

Next step was to make a couple of hand hold cups to fit on the bottom side of the hood skin to seal off the water.To do this l got a couple of 1 qt mixing cups and laid 2 square pieces of 12 oz carbon draped over the cups.No fancy vacuum bagging done here.One thing l messed up on was not thinking about transferring the bar code and the mix ratios from the containers!

I cut the hand holds out and air vents in the back of the hood,sanded down,but still need some finish work.One of the things l have always wanted to do was make the inside of the rear vents look finished.l took a couple of pieces of carbon,prepped the liner and epoxied them down.

Next step was to make a couple of hand hold cups to fit on the bottom side of the hood skin to seal off the water.To do this l got a couple of 1 qt mixing cups and laid 2 square pieces of 12 oz carbon draped over the cups.No fancy vacuum bagging done here.One thing l messed up on was not thinking about transferring the bar code and the mix ratios from the containers!

Attachments

Got several pics from some members (thank you all) on the hood so l could make sure everything was done correctly.

Today l did a final sanding and fitting on the hand hold cups.Sanded the hood area where they went and made up some epoxy to fasten them down to seal them off.Mixed up a small amount of thickened (epoxy) to go around the edges of the cups and laid some 12 oz carbon over.

Came back later after all dried to start fitting all the hood pieces for final assembly.Thats going to be a pita from what l can see right now

I'll have a couple more pics later..

Today l did a final sanding and fitting on the hand hold cups.Sanded the hood area where they went and made up some epoxy to fasten them down to seal them off.Mixed up a small amount of thickened (epoxy) to go around the edges of the cups and laid some 12 oz carbon over.

Came back later after all dried to start fitting all the hood pieces for final assembly.Thats going to be a pita from what l can see right now

I'll have a couple more pics later..

Attachments

Here is the hood,liner,and horns ready for assembly.They are cut,trimmed and fitted.And l kept the bar code! @ScottS

Attachments

Last edited:

I needed to call Nashville yesterday because it's been over a month now since l went to the local county clerks office to register the hull and get an HIN.Lady l spoke to was just getting around to processing my paper work.This is a new system to me since the last hull lm built.She said it would be approved and mailing the hull ID this week! So it went through!

Big Kahuna

Administrator

- Location

- Tuscaloosa, AL

Scraggly made me some! Still need to install!

- Location

- wichita, ks

I 3d print them pm me if interested

Made some progress today on the hood.l got the skin bonded to the liner.lts drying now.As l figured a lot had to happen in a short amount of time.Mixing up the epoxy,thickening it,adding carbon shreds,and laying out a bead all the way around the edges,also putting some epoxy between the two parts to get a good bond all over.Then clamping it all together.l still have to bond the two horns in the front,then it will be done.

Ok,so l have to admit to something l did last weekend trying to bond the hood together.l mixed up a batch of resin but just after mixing in the Cabasil l noticed the container getting warm.l had 2 hot spots.Long story short the mix kicked on me.l wasn't able to use it.A number of things might have caused this if you have ever worked with epoxy,but l screwed up! How? I was using U S Composite's 3:1 medium speed hardener.Still wondering? Not shaking the hardener long enough is the answer.They use a half and half mix of fast and slow hardeners to make the medium.So when you are using this material,shake at the minimum of 3 minutes.Lesson learned

Ok,so l have to admit to something l did last weekend trying to bond the hood together.l mixed up a batch of resin but just after mixing in the Cabasil l noticed the container getting warm.l had 2 hot spots.Long story short the mix kicked on me.l wasn't able to use it.A number of things might have caused this if you have ever worked with epoxy,but l screwed up! How? I was using U S Composite's 3:1 medium speed hardener.Still wondering? Not shaking the hardener long enough is the answer.They use a half and half mix of fast and slow hardeners to make the medium.So when you are using this material,shake at the minimum of 3 minutes.Lesson learned

Attachments

ProSouth

Seriously, Don't be a dick.

- Location

- kawasakis suck

I’ve seen tem pull a superfreak out of his van in 3 pieces and literally just hand it to somebody...”here take this”. Probably weighed 35-40lbs in that form, if that. I know don usually builds his in kit form because he has it down to a science now. He has particular things he wants or adds that manufacturers either won’t do it to his standards, or have no interest in adding it the way he wants.How did come across a hull in this form, is it a kit or something? Freaks need this much assembly ?