- Location

- Northern Nevada

if your machine is set up for CNC, Autodesk Fusion 360 might be somthing cool to check out. its offered for free in some applications

good point! I learned programming at the console using a calculator, blueprint, and G code. definitely makes it nice to program on a pc, then be able to read the code as it runsI already have Fusion and Inventor, just no time to sit down and learn them yet.

Plus by doing it the long way, I get a better understanding of tool path and what my machine is actually capable of so when I do start programming, I actually know what to program.

You can't program tool path if you don't know what tool path is, lol.

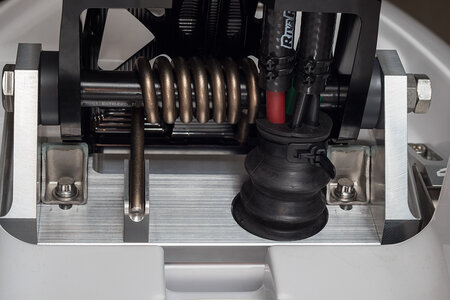

nice piece bro.I finally finished my prototype steering system. I run obnoxiously wide bars and wanted a knee-friendly design that wouldn't wear out, loosen over time or corrode in fresh/saltwater. So far it glides like glass with any tension one could want. It runs on bronze bushings and uses most Boxxer/Fox pattern MTB direct-mount stems. That leaves handlebar options wide open to any 31.8mm or 35mm MTB bar depending on stem choice.

I fabricated all of the components by hand on my manual mill. At some point I might have them properly CNC'd. First I need to test the system and make sure no issues arise or design changes are needed.

There's a good 30+ hours of design and fab time here, probably more.

View attachment 328900

My belt drive kit should be here any day now so I finished up the wiring changes to convert my spindle from a 1HP 90VDC motor to a 1.5HP 3PH motor. In addition to now being controlled from the CNC software, it will also increase my speed range from 80-2500 to 80-8000 RPM.

To test it all out, I hooked up the VFD for my test bench to my CNC controller and just finished writing programs to automate my test procedures for CDI's and Stators.

When are your timing adjustable oem cdis coming out?!

Finished fabricating my handlepole bracket over the weekend. I wanted something that didn't exist and had to make it myself. The three main goals were to align the stock cable bellows with the right side RRP tube, use the OEM handlepole spring, and have enough room to run double nuts on the end of the bolt. The pole stops are OEM Kawasaki with ARP bolts for strength.

100% hand-made on the manual mill.

Only mistake I made was not putting the stops forward enough. I had to move them north a bit.

View attachment 333607

View attachment 333608

Dude I need this my passenger seat in my 04 won't go up and downNot a big job today but certainly one where I am glad I own a lathe. I used it to repair the power seat motors in my Dodge Ram.

I yanked the two little motors that control the front and rear up/down and found they both had a stripped gear. I checked on eBay and found a seller that just happened to be local.

30 minutes later, I have them in my hand and it's time to break the motors down, machine down the shafts and fit the new gears.

2 hours and $110 later, I have fully adjusting power seats again.

Dude I need this my passenger seat in my 04 won't go up and down