Vumad

Super Hero, with a cape!

- Location

- St. Pete, FL

I think I got the tool auto-zero setup today. The probe was already there but there wasn't any scripts to run the button.

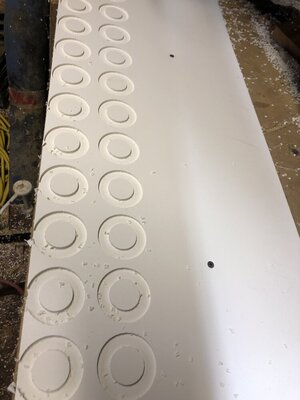

I appreciate it but I am not ready for expensive tooling yet. The 1/8" endmill I broke was a $40 carbide endmill. The machine came with a lot of good tooling but it's not good for learning. I hope to be moving to that at some point, but I need some cheaper stuff to learn with for now. The "value" tool, a quality tool for a low price, is much more appropriate for me presently than a better quality tool, because, well, bad things are happening here.

I don't really want to get too involved with this because I haven't been actively into the machine shop industry for a few years now aside from just some small time manual milling. So my knowledge is massively forgotten now but I can say that machining tools are only as good as you're willing to pay for. When I was dedicated to working with the Eumach mill at the machine shop I very often would use a range of face milling tools but the most common were the 1.5", 2" and 4" button cutter tools. The nice thing about them is the buttons can be indexed (rotated) one seat position and you have a fresh cutting edge again. They're not cheap but they last a very long time if you are smart about your use with them. Don't allow the buttons to become loose, it does happen but if you pay attention to them you can catch it before it becomes a problem. A loose button will spin over the seat formation and round it out making it useless, the buttons will never stay tight in there again eventually destroying the buttons. It was my favorite cutter to use though. Use all inserts at the same time to remove larger amounts of material, scale back to one insert for facing. The more inserts you use, the slower you need to spin your cutter. Same goes for 4 flute end mills, they don't need to be spun at 10k RPM, it was very common place for me to only need between 1000 and 2500 RPM. Anything faster and we would get too much chatter eventually destroying the end mill. 2 flute end mills can be run faster though but it also depends largely on the materials you're using it on. We primarily used Sandvik tools on our mills, here is a link to the button cutter and one more to their homepage which has a feed and speed calculator for general reference purposes only. The calculator is not setting the standard, only suggestive but should get you close enough for most typical materials.

Sandvik Coromant

www.sandvik.coromant.com

Sandvik Coromant

www.sandvik.coromant.com

I appreciate it but I am not ready for expensive tooling yet. The 1/8" endmill I broke was a $40 carbide endmill. The machine came with a lot of good tooling but it's not good for learning. I hope to be moving to that at some point, but I need some cheaper stuff to learn with for now. The "value" tool, a quality tool for a low price, is much more appropriate for me presently than a better quality tool, because, well, bad things are happening here.