- Location

- Ontario, Canada

Footholds

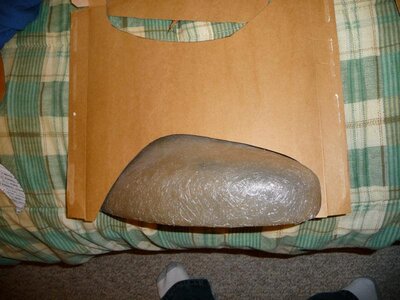

Since footholds are one of the first mods most riders are recommended to do I figured I would start there. My first order of business was to get a template figured out. Once I received my EME (Eric Malone) footholds (http://www.ericmalone.com/Merchant2/merchant.mvc?Screen=PROD&Product_Code=CFH&Category_Code=APA), I took the cardboard lid from my new work boots box and started drawing an outline of the hold but only a small one. The point was to get the hold to slide into the template toe first, and wrap it around behind the template. Eventually I found that sweet spot for a close fitting outline that fit the hold nice and snug, but also had lots of face contact with the flare on the holds.

Then I took my template out, measured from the front of the tray toward the back and drew my template outline. You will notice that I only went 14 inches back from the front of the tray...not a good call. I should have measured 16 inches back because the right hold cutout had about 3 inches of the exhaust tube protruding on an upward angle toward the front of the ski and wouldn't allow the hold to sit down flat on the tray.

To cut out the hole for the hold I used a Dremel rotary tool with a 90 degree attachment and a fair number of cut-off discs. A lesson learned, those little red fiber washers on the disc arbor actually have a purpose. They secure the discs from spinning on the arbor shaft while using the Dremel. I burnt out the center of a few discs because they weren't there at the time. During the cutting, I found that running the cut-off disc in most of the way to the arbor will make sure the hull gets properly cut and not have any SMC fibers still holding on.

Next, using a small pry bar I removed the cutouts and yes they were a little bit tough to peel out of there due to that foam being stuck to them. The pieces stuck to the foam sounded like the hull was splitting as I was prying them out but that was all it was...foam stuck to pieces. I dug out enough foam to squeak the holds into place and what little air space there was left around the holds inside the hull, I re-packed with some of the foam I dug out for the placement of the holds. I then installed my holds, and used some stainless machine screws to keep them in place, I think I used #10's but can't really remember now.

Finally came the glass work. I laid out my first sheet as it appears in the pic and tried to tuck in my upright strips so they would stay in place on their own while I painted on some resin. The strips actually stayed in place reasonably well, of course there were a few that had to be positioned after a dab or two of resin was in place first but that was to be expected. I did this process about 3 times and used the woven fiber type of glass sheet instead of the style that looks like a screen. The woven style is supposed to be much stronger over the screen style. I also did it this way because I kept in mind that once the holes for the footholds are cut out, the structural rigidity decreases too so I wanted the strength to keep my tray going for hard landings and beginner grade freeride crashes. When doing the glass work though, I also made it a point of allowing the glass to cure between each layer. 3 layers of woven fiber glass, 3 cure times.

One quick note, it is a dirty, dusty and not good for the lungs situation. If anyone does this I really recommend using at least a P100 certified breather mask because it is safe to use with paint fumes, resin fumes, glass dust, and other hazardous materials such as asbestos. I also really recommend getting some nitrile gloves and a long sleeved shirt for this because it is also very itchy and a sticky mess to work with. Forgot to mention safety glasses, when the cut-off discs explode (and some of them will) the pieces go everywhere...including to your face.

Since footholds are one of the first mods most riders are recommended to do I figured I would start there. My first order of business was to get a template figured out. Once I received my EME (Eric Malone) footholds (http://www.ericmalone.com/Merchant2/merchant.mvc?Screen=PROD&Product_Code=CFH&Category_Code=APA), I took the cardboard lid from my new work boots box and started drawing an outline of the hold but only a small one. The point was to get the hold to slide into the template toe first, and wrap it around behind the template. Eventually I found that sweet spot for a close fitting outline that fit the hold nice and snug, but also had lots of face contact with the flare on the holds.

Then I took my template out, measured from the front of the tray toward the back and drew my template outline. You will notice that I only went 14 inches back from the front of the tray...not a good call. I should have measured 16 inches back because the right hold cutout had about 3 inches of the exhaust tube protruding on an upward angle toward the front of the ski and wouldn't allow the hold to sit down flat on the tray.

To cut out the hole for the hold I used a Dremel rotary tool with a 90 degree attachment and a fair number of cut-off discs. A lesson learned, those little red fiber washers on the disc arbor actually have a purpose. They secure the discs from spinning on the arbor shaft while using the Dremel. I burnt out the center of a few discs because they weren't there at the time. During the cutting, I found that running the cut-off disc in most of the way to the arbor will make sure the hull gets properly cut and not have any SMC fibers still holding on.

Next, using a small pry bar I removed the cutouts and yes they were a little bit tough to peel out of there due to that foam being stuck to them. The pieces stuck to the foam sounded like the hull was splitting as I was prying them out but that was all it was...foam stuck to pieces. I dug out enough foam to squeak the holds into place and what little air space there was left around the holds inside the hull, I re-packed with some of the foam I dug out for the placement of the holds. I then installed my holds, and used some stainless machine screws to keep them in place, I think I used #10's but can't really remember now.

Finally came the glass work. I laid out my first sheet as it appears in the pic and tried to tuck in my upright strips so they would stay in place on their own while I painted on some resin. The strips actually stayed in place reasonably well, of course there were a few that had to be positioned after a dab or two of resin was in place first but that was to be expected. I did this process about 3 times and used the woven fiber type of glass sheet instead of the style that looks like a screen. The woven style is supposed to be much stronger over the screen style. I also did it this way because I kept in mind that once the holes for the footholds are cut out, the structural rigidity decreases too so I wanted the strength to keep my tray going for hard landings and beginner grade freeride crashes. When doing the glass work though, I also made it a point of allowing the glass to cure between each layer. 3 layers of woven fiber glass, 3 cure times.

One quick note, it is a dirty, dusty and not good for the lungs situation. If anyone does this I really recommend using at least a P100 certified breather mask because it is safe to use with paint fumes, resin fumes, glass dust, and other hazardous materials such as asbestos. I also really recommend getting some nitrile gloves and a long sleeved shirt for this because it is also very itchy and a sticky mess to work with. Forgot to mention safety glasses, when the cut-off discs explode (and some of them will) the pieces go everywhere...including to your face.

Attachments

-

Footholds 2.jpg40.8 KB · Views: 156

Footholds 2.jpg40.8 KB · Views: 156 -

Footholds 1.jpg74 KB · Views: 166

Footholds 1.jpg74 KB · Views: 166 -

Footholds 10.jpg52.3 KB · Views: 189

Footholds 10.jpg52.3 KB · Views: 189 -

Footholds 9.jpg61.3 KB · Views: 179

Footholds 9.jpg61.3 KB · Views: 179 -

Footholds 8.jpg32.2 KB · Views: 158

Footholds 8.jpg32.2 KB · Views: 158 -

Footholds 7.jpg47.1 KB · Views: 161

Footholds 7.jpg47.1 KB · Views: 161 -

Footholds 5.jpg48.7 KB · Views: 156

Footholds 5.jpg48.7 KB · Views: 156 -

Footholds 4.jpg35.9 KB · Views: 151

Footholds 4.jpg35.9 KB · Views: 151 -

Footholds 3.jpg21.6 KB · Views: 152

Footholds 3.jpg21.6 KB · Views: 152 -

Footholds 6.jpg38.4 KB · Views: 151

Footholds 6.jpg38.4 KB · Views: 151

Last edited: