- Location

- New York Crew

This season as usual is way too busy for me to find time to build another ski, but as usual I sold everything I had and decided to start new again. This build started a while ago in my head, and I started gathering OEM as well as aftermarket pasts last season. As we all know delivery for parts can keep you off the water for 6 months easily. Especially Pumps, Motors, and Hulls. This was part of the reason I started my planning a year in advance. This time around I decided to go with an Xscream DVX Carbon hull. As anyone knows who has ridden one, it is quite comparable to my older KDX, and rides flat and loose, but hooks when required. I took delivery at WaveDaze as Rick from XScream and Johnny Leftley helped me out. Way too much going on so I had Xscream mount the Pole, steering, bars and all inserts for my build. Rick was great to deal with as usual. Had a visit down there in Nov to confirm exactly what I wanted. I am going to run the black primer with vinyl for a clean look. I plan on this build bein all business, and the look of the ski should match. P&P Performance, TPE, Myself and Patch Motors are providing assisstance on this build/tune.

As most know a build cannot happen without the assistance of many and only the best parts from all over the globe. My thanks goes out to all involved, as this could not be done without YOU.

Parts are from XScream, Fast Elements, East Coast Performance, Yamaha, Jetmaniac, Wizzard Powersports, Rage Composite Works, H20 Products, Thrust, Power Factor Products, Full Spectrum Racing Carburetors, Boyesen Racing.

The build parts will be as follows:

HULL:

2015 XScream DXV, Carbon, with extra layer in the bottom, where specified

Dual scupper, 155 Shoe installed, inserts installed

XScream Carbon Rideplate

XScream Comp length pole Steering and bars

Hydroturf, black cut, smooth, and molded diamond.

PUMP:

H20 155mm Torrent a while ago to try but wasnt allowed to say as it was not yet released was a Skat 14 vein MAG pump, H20 Driveshaft

was a Skat 14 vein MAG pump, H20 Driveshaft

10/18 Skat starter prop, special cuts, and set back

Reduction nozzle bored to 88mm, Steering 92mm

XScream trim with boot

MOTOR:

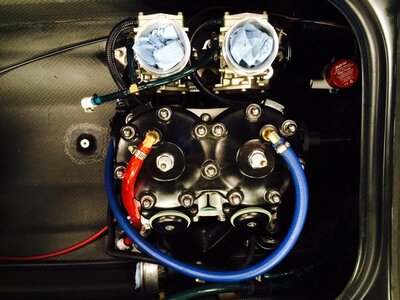

TPE 1105, 10mm 50/50 gas domes Custom work by Erik himself

Boyesen Intake and carbon and glass reeds

Full Spectrum 49mm ALVR 5's, custom for this set up from ED

MSD TL Dual

PFP and Water box

Mikuni remote fuel pump

OEM parts:

S/S Switch

Motor Mounts

Mid shaft housing, and Shaft

Hardware

RN Throttle cable

Steering cable

Coupler cover

A/M Parts:

ADA couplers

ODI Extreme grips

Rule 500 GPH bilge w/ rotary switch

Odyssey battery

I wont go into too many details yet as im trying to get this build done and on the water for testing. There are a lot of custom parts, porting, tweaking, bending, etc that we have now learned on the last few builds that were implimenting here. It all takes time, and is always double what you figure, but worth it when its done correct the first time.

As most know a build cannot happen without the assistance of many and only the best parts from all over the globe. My thanks goes out to all involved, as this could not be done without YOU.

Parts are from XScream, Fast Elements, East Coast Performance, Yamaha, Jetmaniac, Wizzard Powersports, Rage Composite Works, H20 Products, Thrust, Power Factor Products, Full Spectrum Racing Carburetors, Boyesen Racing.

The build parts will be as follows:

HULL:

2015 XScream DXV, Carbon, with extra layer in the bottom, where specified

Dual scupper, 155 Shoe installed, inserts installed

XScream Carbon Rideplate

XScream Comp length pole Steering and bars

Hydroturf, black cut, smooth, and molded diamond.

PUMP:

H20 155mm Torrent a while ago to try but wasnt allowed to say as it was not yet released

10/18 Skat starter prop, special cuts, and set back

Reduction nozzle bored to 88mm, Steering 92mm

XScream trim with boot

MOTOR:

TPE 1105, 10mm 50/50 gas domes Custom work by Erik himself

Boyesen Intake and carbon and glass reeds

Full Spectrum 49mm ALVR 5's, custom for this set up from ED

MSD TL Dual

PFP and Water box

Mikuni remote fuel pump

OEM parts:

S/S Switch

Motor Mounts

Mid shaft housing, and Shaft

Hardware

RN Throttle cable

Steering cable

Coupler cover

A/M Parts:

ADA couplers

ODI Extreme grips

Rule 500 GPH bilge w/ rotary switch

Odyssey battery

I wont go into too many details yet as im trying to get this build done and on the water for testing. There are a lot of custom parts, porting, tweaking, bending, etc that we have now learned on the last few builds that were implimenting here. It all takes time, and is always double what you figure, but worth it when its done correct the first time.

Last edited: