RiverRat

.......

- Location

- Louisville, Ky

Building my 927cc motor for the X-jet. My Lamey PV motor was rocking until my manifold crapped out on me. I was going to continue to run that set up but can't deny the numbers that the 66e (gp800) produces.

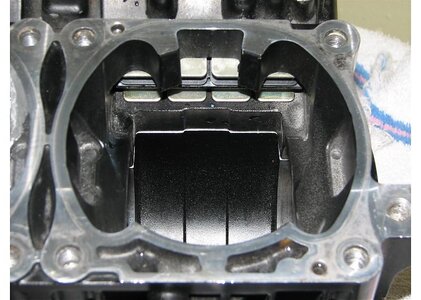

For this build I am using 66v cylinders off a gp1200. I have not done the port mapping of this cylinder but have been told by several people that the port timing is better for low end performance. Jeff from Waterdawgs is providing the cylinders........all media blasted, bored to 87mm and re-nikacil plated cylinders. The nikacil plated cylinder promote better and more uniform cooling while also improving piston acceleration over steel sleeved cylinders. The pistons will be forged wiesco that are lighter and more durable than cast pistons.

More info and pics will follow soon...............

For this build I am using 66v cylinders off a gp1200. I have not done the port mapping of this cylinder but have been told by several people that the port timing is better for low end performance. Jeff from Waterdawgs is providing the cylinders........all media blasted, bored to 87mm and re-nikacil plated cylinders. The nikacil plated cylinder promote better and more uniform cooling while also improving piston acceleration over steel sleeved cylinders. The pistons will be forged wiesco that are lighter and more durable than cast pistons.

More info and pics will follow soon...............