E350

Site Supporter

- Location

- Sacramento Delta

How, with what did you sand/shape your strakes?

How, with what did you sand/shape your strakes?

Your answer is great. Thanks for the tips which I will use!

However, my specific question was what shape and what woulld you use (e.g., tube wrapped with emory cloth) to true the strakes. There was a thread here about how Jacobs trued the hull of his race ski that way back in the day . . .

For the pump shoe, Is it the the fork part bottoming out, or the thicker part that meets up with the pump?

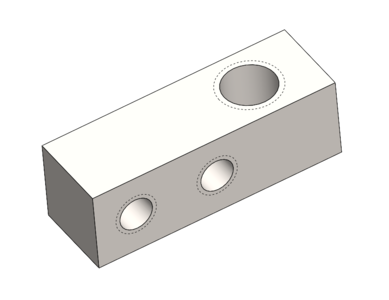

As for the ride plate mount, you could make a new one with the two hull mounting holes in front of the ride plate bolt to shorten the mount away from the cable holder.

Something like this:

View attachment 418767

Move the steer tube.

Grind out the 144Yesterday was fun, lots of grinding and sanding to get this pump shoe into place. I test fit the pump with and without the pump seal. With the pump seal installed, I have half moons visible through the pump mounting holes.

View attachment 419005View attachment 419006View attachment 419007

This should give a nice squish of the pump seal against the shoe. I removed the pump seal and aligned the pump directly over the mounting holes… I have a slight gap at the pump shoe and I believe this is going to fit very well!

View attachment 419008View attachment 419009View attachment 419010View attachment 419011

It also occurred to me while fitting this pump shoe, it is a Worx 144 shoe and my pump is a 148. Do I need to get a different pump shoe for the 148 or just grind out the 144? Let me know what your opinion is on this.

The last thing I did was stand the ski up and fill in the steering cable through hole. After much thinking and debating, I realized the only option was to lower the hole to clear the ride plate mounting block. Booooo!

Squish looks right on. I’d just open up the shoe to 148 with a hand sanding drum.

Mark the back edge of shoe with a sharpie,Any ideas on how to do it accurately? Or is it not that sensitive?