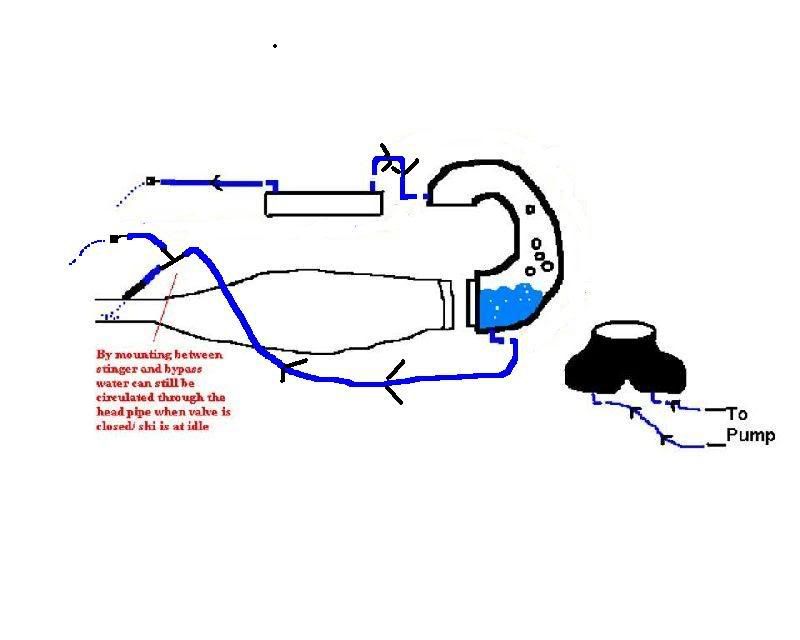

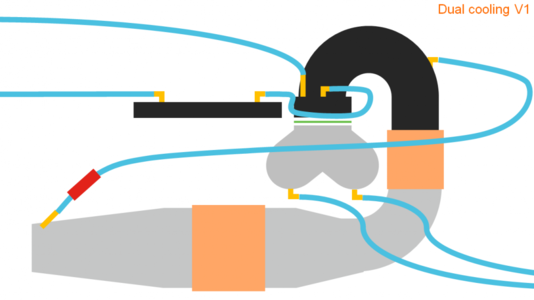

That way above isolates the head/manifold cooling from the pipe cooling. By watching your pissers, you would know where you have a problem if you have a clog, etc. The head pipe is routed backwards in the diagram above- you could switch the entry/exit lines if you want a slightly cooler exhaust.

Edit: Since the water is coming directly into the head pipe, it might be too cold if you reverse the direction. Honestly, it might be too cold either way since the pipe is designed to get water that has already passed through the manifold and out of the head.

Edit: Since the water is coming directly into the head pipe, it might be too cold if you reverse the direction. Honestly, it might be too cold either way since the pipe is designed to get water that has already passed through the manifold and out of the head.

Last edited: