Idok

F1pro

- Location

- Nations oldest muthaF+++kin city

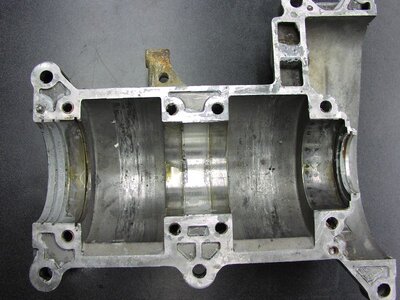

1) We have never seen a defective laby in 10 years of doing this. For that reason, my production guys did not think to measure it. Quite honestly, we are going to be shocked if its too big. Yamaha is very good at such things. Now it could be a Hot Rod or Wiseco laby and that would be a different story. And it's also possible that it is "donut" shaped from getting dropped or something, but we have never seen that either. I am sorry we didn't measure the labby sooner, but it was just not something we thought of at the time.

2) Not sure I understand the question, but yes the OE is turned on a lathe. We blast it clean using an abrasive media that changes the surface finish, but does not change the dimensions (unless it is accidently left in the blasting machine for a week, and it would be smaller, not bigger). And remember, the SBT laby is simply a cleaned up OE laby. We don't make our own.

now wait a minute.

What do you mean noone thought to measure it? This is PRECISELY the reason that Eric drove to Clearwater...He actually saw you that day, but you were involved with something in the tech dept. He told Chris, Julie, and even stephanie time and time again that it was too big. Did noone believe him? Even after he provided measurements???

then again when we spoke with Julie and returned the cases/crank again a week later the same story.......Noone STILL bothered to measure it then? :thinking:

the drive from st. aug to clearwater is over 3 hours........not just down the street..Did I mention that I funded this trip to clearwater as well?

I just dont understand.

Last edited: