BrightE's

Paul

- Location

- Seattle, WA

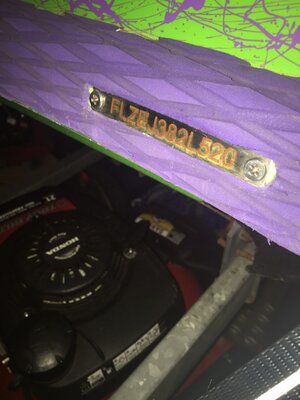

Just got my tags! They look great

Sent from my LG-F350K using Tapatalk

Sent from my LG-F350K using Tapatalk

I thought about that. However, My laser is meant for metals. Some lasers mark plastics well but mine doesn't. There are guys 3D printing some nice plastic ones. I thought about jumping into that but I don't want to steal business from them or force them to compete in a market that only brings in about 500-1000 bucks a year.plastic?

Ya. The original ones I made were 304 and there were widespread issues with those. salt is just such a b***c....I'll have to go back and see if mine have fared any better. I know the one on the outside of the ski still looks good but it got washed down after every ride. The one behind the ebox will be the true teller.

Kudos to you for the upfront and honest response BTW!!!

Edit: I looked back at my thread for the stainless type and mine are 304. According to the following document, 316 should have been the better alloy.

http://www.ssina.com/download_a_file/corrosionfinal.pdf

Ya. The original ones I made were 304 and there were widespread issues with those. salt is just such a b***c....

I debated that, I really did. Still am actually. However, you always have that one customer that ignores the warnings, uses them improperly, then complains to the whole world about your product being crap. I don't know if it's worth it for me to risk it.... I'm trying to get my brand going and the last thing I need is for ANY bad press. I'll think it over....Maybe you could still offer the tags just with this warning attached to them ? I was about to register my ski shortly and then hit you up for a set of these. I don't ride much saltwater and spray my ski down after every ride.

Just a thought

Its always a possibility but I trust that they sent me decent stainless. My laser setting could be the issue like you suggested. It's the only setting on our new laser that produced a black mark that looked decent. The other settings burned the hell out of the tag and left a really rough mark. I absolutely hate our new laser but it's the only one I have access to.Is it possible that your supplier is just sending you junk stainless? Either that or you are etching too deep and exposing too much iron?.?.?.?

Here's some pics of my 304 tags.

Rear tag;

In behind ebox;

Well now OCD has me wondering if rusting would still happen in freshwater due to a problem with my laser setting...I think he is right. I have only marked about a dozen tags with our new POS laser so I don't have good data to prove that this will only happen in salt.

I'll be riding in late March to early April

I'll be riding in late March to early April