- Location

- OR

I feel like I finally accomplished something this weekend!

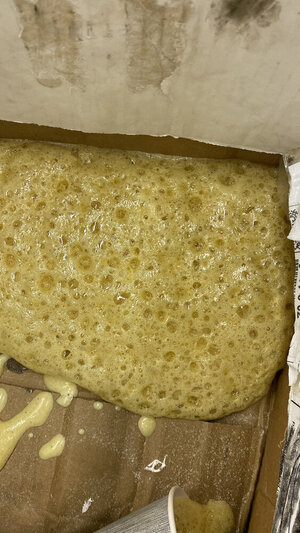

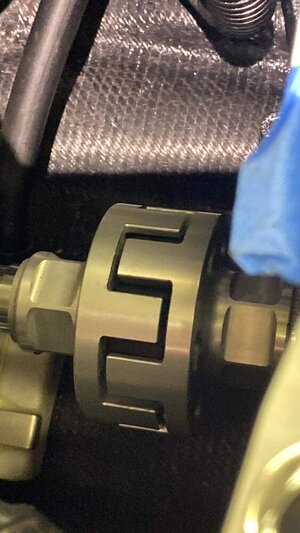

5200 is a mess to work with! But my lines are installed, as well as my intake grate hull inserts!

Some of you guys make spreading the 5200 look easy!

I got the fast cure 5200. So I’ll probably start foaming this week after work. Going to use pink board foam. Any tips or tricks are appreciated!

5200 is a mess to work with! But my lines are installed, as well as my intake grate hull inserts!

Some of you guys make spreading the 5200 look easy!

I got the fast cure 5200. So I’ll probably start foaming this week after work. Going to use pink board foam. Any tips or tricks are appreciated!

Attachments

-

E13F22E8-6445-4796-8B93-00E4A049BE3F.jpeg162.6 KB · Views: 40

E13F22E8-6445-4796-8B93-00E4A049BE3F.jpeg162.6 KB · Views: 40 -

896F7546-6A11-4A1C-9B4B-9EA959D6A09A.jpeg81.6 KB · Views: 43

896F7546-6A11-4A1C-9B4B-9EA959D6A09A.jpeg81.6 KB · Views: 43 -

5594613C-B6A9-40EF-9D9A-E7D103C798A1.jpeg217.9 KB · Views: 40

5594613C-B6A9-40EF-9D9A-E7D103C798A1.jpeg217.9 KB · Views: 40 -

53867F54-37E9-48EF-BA19-65B2B5737B0B.jpeg174.4 KB · Views: 36

53867F54-37E9-48EF-BA19-65B2B5737B0B.jpeg174.4 KB · Views: 36 -

CF67B9BC-51F2-4ECB-B075-59D037127AEB.jpeg170 KB · Views: 35

CF67B9BC-51F2-4ECB-B075-59D037127AEB.jpeg170 KB · Views: 35 -

47D127B1-824C-43C1-AED4-AC2677B3D7B2.jpeg262.8 KB · Views: 32

47D127B1-824C-43C1-AED4-AC2677B3D7B2.jpeg262.8 KB · Views: 32 -

DC3FBA2B-8B78-47D2-AAFA-9389113C6348.jpeg142.7 KB · Views: 34

DC3FBA2B-8B78-47D2-AAFA-9389113C6348.jpeg142.7 KB · Views: 34