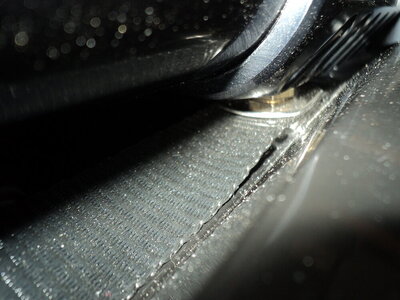

Put down the pipe after the fuel tank install ? I figured you'd of known I was on the crack pipe after the first post when I said I WANTED to do turf !!! Lol.Was gonna say put down the pipe and go to bed when I saw the first image of that hot mess of a fuel tank install.. Glad I didn’t, after your next coupe posts, it looks very interesting, very creative sir, I like it!

Thanks !!!