You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Project RiverRat II

- Thread starter RiverRat

- Start date

RiverRat

.......

- Location

- Louisville, Ky

Sweet, in Jeffspeak that means you might have it in time for Lanier 2009 :biggthumpup:

I have been pretty straight forward with him. I told him that I would like to put it in the build off but that is only if I get the hull by March. I am not rushing the project like I did last year. He has been really busy lately but when he says that he will crank it out by late Feb I am going to hold him to that. If I get it in April or May thats great but it won't go in the build off. The bottom deck was completed in early December and I asked him for some pics but have yet to get any............I am not jumping to any conclussions. I know he can make a nice ski and that is why I chose him to build my hull. I am 100% confident that he will complete this hull on time and it will be bitchin :headbang:

Last edited:

Mile9c1

X-H2O.com

- Location

- Grand Rapids, MI

My bottom deck was completed in early December... 2005 :haha:

RiverRat

.......

- Location

- Louisville, Ky

My bottom deck was completed in early December... 2005 :haha:

I am not sweating it :smoker:

RiverRat

.......

- Location

- Louisville, Ky

Made some more progress today. Got some parts bach from LPW. The headpipe/manifold ports were opend up from 44mm to 48mm, ordered a set of SS bolts for the headpipe (highly reccomend), new adjustable screws and new pump bearings. I swear with all the mods done to this b-pipe it would cost over $1000 new. You can see the difference between a standared FP manifold and the one that is modified. That should flow a little more.  urr: I am anxious to see how the motor runs b/c I always thought that this would make an improvement on that lamey motor w/ dual 48's. Now the exhaust can theoetically flow as much as the intake can provide. Now it can be shipped off for Jet-Hot coating.

urr: I am anxious to see how the motor runs b/c I always thought that this would make an improvement on that lamey motor w/ dual 48's. Now the exhaust can theoetically flow as much as the intake can provide. Now it can be shipped off for Jet-Hot coating.

Attachments

RiverRat

.......

- Location

- Louisville, Ky

TBM pump cone pics.............

Note: Since I am using a -3mm cutback impeller, I found that I have to remove 1-2mm off the front of the TBM assembly. The impeller hits before threading on all the way. No big deal, couple passes on a belt sander should do the trick.

Note: Since I am using a -3mm cutback impeller, I found that I have to remove 1-2mm off the front of the TBM assembly. The impeller hits before threading on all the way. No big deal, couple passes on a belt sander should do the trick.

Attachments

Last edited:

RiverRat

.......

- Location

- Louisville, Ky

Intake manifold mods

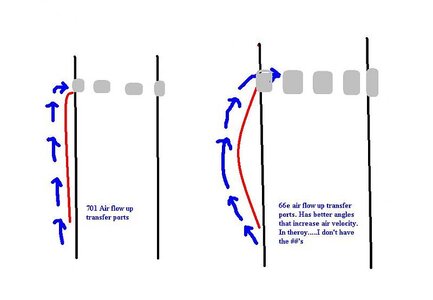

Asked around to see who could do this and Chucky from Team Scream said he would give it a whirl. Recessing the reed cage assembly into the manifold and removing material at the mointing point for the carbs. This should make the intake track nice and short, lessening the angle and distance that air has to flow before it hits the reed cage assembly and acts as a reed spacer all at the same time. Hopeing that this mod will contribute to some added throttle response. I figur the reed cages can be recessed about 7mm and anouther 6-7mm can be taken off the mounting surface of the carbs. -14mm on the runner length.................not to bad IMO. The RIVA manifold is a nice quality and thick cased peice so it is perfect for this type of modification.

I know that allot of guys get the intake runners really ruff to promote better fuel atomization. This never made allot of sense to me. In the cases sure...........that way it will keep the fuel atomized all the way up through the transfer ports. I think that if you have a good set of carbs that atomized the mixture well it should be a non-issue before the reed cages. I plan to keep the intake runners pretty smooth (150 grit) on this system so I can get clean unobstructed flow through the reed cages. I just don't see the point in having a smooth carb bore, then make the air very turbulant by making the intake very ruff, then try and straighten out the air by using a stuffer or something of that nature. I want it to flow fast, straight and smooth through the reed cages to get as much air/fuel crammed into the cases before the valves close.

Attachments

Last edited:

RiverRat

.......

- Location

- Louisville, Ky

Not to get off track but pretty pumped about this. :sneaky: :sneaky: Secured a platform to do some R&D on next year. This modified (bolt on's) motor powered the gp800 to speeds of 70mph (clocked) :bigeyes: Not something I am taking lightly. Plan to do allot of research and careful preparation/ parts selection to get it dialed in. The numbers on these motors are just way to inticing to leave it alone. Here are the specs in stock form:

Rated Horsepower

120 hp @ 7,000 rpm

Engine Type

2-Cylinder, 2-Stroke

Bore/Stroke

80mm x 78mm

Displacement

784cc

Fuel

Regular Unleaded

Type of Intake

Reed Valve

Type of Scavenging

Loop-Charged

Type of Exhaust

Wet

Type of Lubrication

Oil Injection

Cooling

Water

Ignition

Digital

Compression Ratio

6.6:1

Carburetor/Injection

(2) Mikuni Super BN 44 with Accelerator Pump

Spark Advance

5°

Ignition Timing

15„a BTDC ¡V 20„a BTDC

Spark Plug

BR8ES

Pump

155mm Axial Flow Single Stage with Q.S.T.S.

Transmission

Direct Drive from Engine

Impeller

3-Blade, Stainless Steel (13.2 pitch)

Length

115.4” (2.93m)

Width

45.3” (1.15m)

Height

40.2” (1.02m)

Seat Length

37.4”/35” (.95m/.89m)

Dry Weight

590lbs (267.6kg)

Fuel Capacity

15.9 gal (60L)

Reserve Fuel Capacity

2.64 gal (10L)

Oil Capacity

1.45 gal (5.5L)

Vehicle Capacity

1, 2 Persons

Storage Capacity

4.23 gal (16L)

Rated Horsepower

120 hp @ 7,000 rpm

Engine Type

2-Cylinder, 2-Stroke

Bore/Stroke

80mm x 78mm

Displacement

784cc

Fuel

Regular Unleaded

Type of Intake

Reed Valve

Type of Scavenging

Loop-Charged

Type of Exhaust

Wet

Type of Lubrication

Oil Injection

Cooling

Water

Ignition

Digital

Compression Ratio

6.6:1

Carburetor/Injection

(2) Mikuni Super BN 44 with Accelerator Pump

Spark Advance

5°

Ignition Timing

15„a BTDC ¡V 20„a BTDC

Spark Plug

BR8ES

Pump

155mm Axial Flow Single Stage with Q.S.T.S.

Transmission

Direct Drive from Engine

Impeller

3-Blade, Stainless Steel (13.2 pitch)

Length

115.4” (2.93m)

Width

45.3” (1.15m)

Height

40.2” (1.02m)

Seat Length

37.4”/35” (.95m/.89m)

Dry Weight

590lbs (267.6kg)

Fuel Capacity

15.9 gal (60L)

Reserve Fuel Capacity

2.64 gal (10L)

Oil Capacity

1.45 gal (5.5L)

Vehicle Capacity

1, 2 Persons

Storage Capacity

4.23 gal (16L)

Attachments

Last edited:

RiverRat

.......

- Location

- Louisville, Ky

Just as an example. 120hp stock w/ stock electronics, exhaust and dual 44mm carbs. Put a WDK exhaust, bump the compression from 120psi (stock) to 150psi, dual 48's, TL, v-force reeds...........on a stock stroke which is equivilent to a 10mm stroker 62t. I am willing to bet it would hook up with a 144mm pump, a TBM cone and the correct pitch c-75 impeller. Not sure what the exact HP numbers would be on that set up but I am willing to bet 150-160 is not out of the question. If you were to do a BB kit from either WDK or GroupK (87mm and re-nickisil plate the cylinders for faster piston speeds)...........that thing would flat out thump. Maybe do a 144mm mag set back on that set up. The big thing is getting that power to hook up.

Attachments

Last edited:

- Location

- Hutchinson, Kansas

did you buy that gp ebay motor? the one with all the mods?

RiverRat

.......

- Location

- Louisville, Ky

did you buy that gp ebay motor? the one with all the mods?

check your pm box

- Location

- Hutchinson, Kansas

good job, smokin good deal.

Mile9c1

X-H2O.com

- Location

- Grand Rapids, MI

Will those pipes fit in an X-Jet?

RiverRat

.......

- Location

- Louisville, Ky

Will those pipes fit in an X-Jet?

Possibly.

RiverRat

.......

- Location

- Louisville, Ky

Doing some additional port work to the cases and ruffing up the tranfer ports of the cylinders. The first pic you can see how the center port overlapped the transfer port in the middle of the cases. Raised the roof and widened that area to allow better flow through that port. Not much but I wanted to try it out but just did not do it last year as I wanted to get the ski back on the water.

Pics are:

*Left done right normal

*Close up of modification

*Close up before mod

*Both modified

Pics are:

*Left done right normal

*Close up of modification

*Close up before mod

*Both modified

Attachments

Last edited:

Y

yamaslut

Guest

do you actually ride jet skis?????

RiverRat

.......

- Location

- Louisville, Ky

do you actually ride jet skis?????

2 weeks out of the year I am on it :biggthumpup:

Y

yamaslut

Guest

2 weeks out of the year I am on it :biggthumpup:

I guess you can call yourself one then.... just barely

RiverRat

.......

- Location

- Louisville, Ky

I guess you can call yourself one then.... just barely

It just occured to me that no one has achually seen me ride :haha: Lanier I was still building and Daytona I was just hanging out