very nice RR....going back a couple of posts, you mention moving the carbs and reeds closer together to shorten the track..

I always thought it was beneficial to LENGTHEN the track...ie reed spacers, velocity stax etc etc......

Referencing my previous experience w/ cars, a lobger runner will have a different power band than a shorter intake track. Typically the short track will allow for better throttle response and low end perofrmance. A velocity stack is typically before the throttle butterflies. They starighten out the flow and operate better as RPM's increase. Look at the set ups on crotch rockets. They typically have carbs mounted right onto of the cylinder head. The manifold is nothing more than a rubber coupler between the carb and head. They also have velocity stacks before the butterflies to increase that upper RPM power. Some manifolds produce the low end torque, others opt to increase power in the upper RPM's by smoothing out that flow and increasing

runner length. There are allot of variables concering this and my experience tells me short intake track for low end power. Look at the sidedraft carbs on a gp800, crotch rockets, Chevy LT1/LT4 manifolds, edlebrock manifold designs vs their rated performance RPM's.

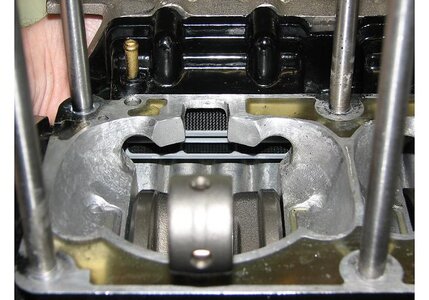

On this set up I want fast,

smooth flow through the reed cages. I am not worried about fuel atomization and don't want to rough up the track too much. If the fuel can't stay atomized between the bomb site and the reed cages my carbs suck :haha: The fuel charge is being drawn/sucked the through the reeds anyway. Cases will be rough but the intake will go over with a 120 grit sanding wheel.

Reed spacers are designed to move the reeds back to increase petal life. Allot of builders find it benificial to epoxy the fingers of the cases when adding a reed spacer. Boyesen and Full Spec designed a manifold that does exactly what this mod does, move the reed cages back while not adding additional case volume.