E350

Site Supporter

- Location

- Sacramento Delta

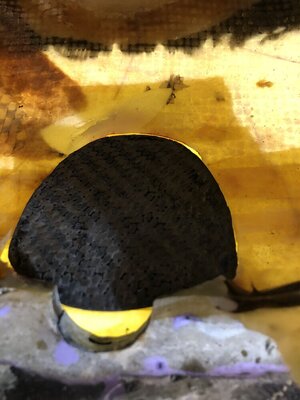

Interesting thing you guys are doing with the rails. Can I assume that it is to make the ski hold a carve better when on its side?

The thing I notice about the FX-1 vs the SN SJ or even the 550sx is that while the latter skis seem to somewhat want to roll upright out of a turn, the FX-1 will stay on its side unless steering and body weight shift are directed to the outside of the turn.

Do you guys notice this too?

Do tubbies help the front roll up easier out of a turn?

The thing I notice about the FX-1 vs the SN SJ or even the 550sx is that while the latter skis seem to somewhat want to roll upright out of a turn, the FX-1 will stay on its side unless steering and body weight shift are directed to the outside of the turn.

Do you guys notice this too?

Do tubbies help the front roll up easier out of a turn?