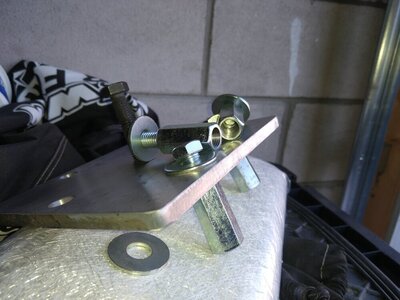

Getting pretty close to finished on my beach cart . Would of finished but ran out of argon on a Sunday .

I so want a second little bottle for just that reason!

I just got my 150 filled a few weeks ago and forgot to close the valve while taking a break from my Mill Enclosure build and lost over half the damn bottle over a 4 day period.

I was so pissed with myself.

I hung a WEN Air Filtration system from the ceiling yesterday to help with the air quality in the garage while I'm working on certain projects. It's not really built for welding fume extraction but it will help for small welding jobs, grinding and sanding, plasma cutting, wood working and the aerosols created when I'm doing vacuum degassing.

I went with the big unit that can pull up to 1044 CFM so it should turn over the garage at least 10 times an hour on high and greatly reduce mask time.

Now to find a PECO filter that will fit in this unit so it'll also take out some VOC's.