- Location

- ARGENTINA

help

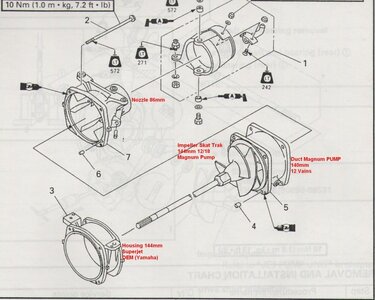

Magnum Pump I have a turbine and a propeller 140mm to 144mm 12/18 Magnum already installed in the jet and I can not do the backflip.

I advised to change to achieve the backflip?

:brap::chairshot:

Magnum Pump I have a turbine and a propeller 140mm to 144mm 12/18 Magnum already installed in the jet and I can not do the backflip.

I advised to change to achieve the backflip?

:brap::chairshot:

FOR YOUR PUMP YOU MUST INSTALL 145 SET BACK PUMP SKAT TRACK WITH 14 VEINES, skat trak don t make bigger

on my dasa +16 WITH TWIN 48FS NOVI , i have this set up CARBS:

low 110

HIGH 130

2,5

115 SPRING

AND IT S GOOD WITH 12,8KG COMPRESSION, with 90,5 MM PISTONS

GOOD LUKE