What l want to know is how do all the out of work comedians end up on the X,Boyer!!! Real freakkin funny!!! lol:deadhorse:

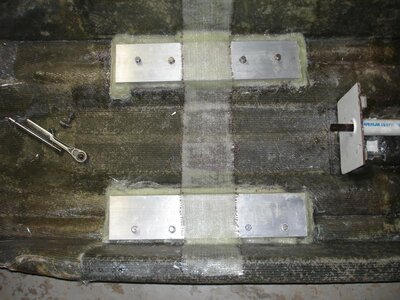

Whatever... I thought that was pretty damn funny. Kenny was one of the first ones to take delivery of the complete hull. Curious if he has a hood yet though...