Big Kahuna

Administrator

- Location

- Tuscaloosa, AL

Do all glass work first, paint last.

That's crazy.Do all glass work first, paint last.

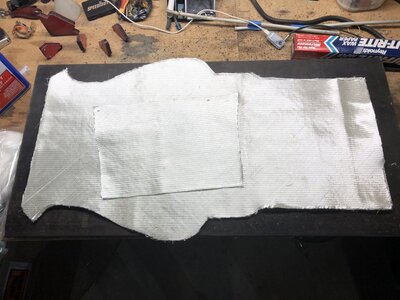

Thanks. I've lost track of how many hours it has taken at this point but it has to be over 100. It's easy to lose motivation just thinking about sanding for hours then scuff, clean apply more resin, wait 12 hours to dry and then sand more. It's easy to cut corners thinking about "nobody is going to notice that" or "the bottom is just going to get torn up anyway" which are both probably true lol. Sometimes I wish I just got another ski but the reality is most of them would have some body damage and soaked foam, or at least that's what I keep telling myself. It's a good learning process at least.You have done a ton of work to that ski! Kudo's to you on hanging in there! A lot of guys would have given up by now.

Thanks, that's what I'll do.Do all glass work first, paint last.

I appreciate it. I really just need a new midhsaft housing right now since the bushing is loose in mine.I see you're from Cumming. We're just down the road in Dawsonville. If you need any Yamaha stuff or SJ stuff, we have a ton of it.

Check these guys out in Cumming to have your parts repowedercoated, you can also have the exhaust parts ceramic coated for better performance

http://www.procryo.com/

Looking good. I would put a piece of tape over the pump bolt inserts and then 5200 on top, just my two pennies

pretty dedicated. much respect! looking forward to more updates