You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Super Jet Project Dance-floor

- Thread starter Req

- Start date

- Location

- native idahoan

Color doesn't matter. Red or white. I have both colors on my skis and then that has never been an issue, it's the chemical composition of what's inside that they're looking for

Sent from my SM-G892U using Tapatalk

Sent from my SM-G892U using Tapatalk

I ordered 7 yards of 17 Oz by axe without mat and some more resin. Also got titanium dioxide die so I can stain the engine bay White.

I found this little strainer at Academy Sporting Goods. It fits inside a 2in PVC tube perfectly and has a three-quarter inch thread. I think I'm going to 5200 it in and it will act as both a pre-screen as well as a Scupper plug if I ever ride surf. The only downside is it picks up the outlet by 1/2 inch so it won't evacuate as much water but I guess that's what the electric bilges are for.

I can also drill out the plastic and that would lower the pickup point but I wouldn't be able to plug it with the threads anymore obviously. I'm sort of torn. I can always plug it externally if push comes to shove.

I found this little strainer at Academy Sporting Goods. It fits inside a 2in PVC tube perfectly and has a three-quarter inch thread. I think I'm going to 5200 it in and it will act as both a pre-screen as well as a Scupper plug if I ever ride surf. The only downside is it picks up the outlet by 1/2 inch so it won't evacuate as much water but I guess that's what the electric bilges are for.

I can also drill out the plastic and that would lower the pickup point but I wouldn't be able to plug it with the threads anymore obviously. I'm sort of torn. I can always plug it externally if push comes to shove.

Big Kahuna

Administrator

- Location

- Tuscaloosa, AL

There is no need for that. You will be preventing water from escaping by adding that.

SXIPro

JM781 Big Bore

- Location

- Here on the 'X' mostly

Can't lost zip ties and such go down the tube and 'hang' the ball up keeping it from sealing?There is no need for that. You will be preventing water from escaping by adding that.

Edit: I was a bit slow on the draw on that one.

Big Kahuna

Administrator

- Location

- Tuscaloosa, AL

Mesh over the hole would be fine. but that is constricting your flow. Defeating the purpose. You want as all of that opening (PVC) open to remove the water.

hornedogg79

dodgin' bass boats

Just remove the plastic part and 5200 the screen on. What you should've bought was a RV furnace vent screen. As for your hood I think that'll be plenty of air hole. The 760 in my fx1 runs great with just the two tiny stock rear holes. Keep in mind if you run a bilge pump(s), each outlet is also a 3/4" air inlet if not pumping water.

Sent from my SM-G930V using Tapatalk

Sent from my SM-G930V using Tapatalk

Big Kahuna

Administrator

- Location

- Tuscaloosa, AL

yes, that can happen.Can't lost zip ties and such go down the tube and 'hang' the ball up keeping it from sealing?

Edit: I was a bit slow on the draw on that one.

Slowly plugging away at it. I got the foam laid in about as tight as I can. I debated back and forth between expandable foam and no expandable foam and after debating the pros and cons with my father I settled on a combination of the two. I put as much blue foam as I could fit. It should take a very small amount of two-part. We did settle on a French drain solution to make sure that water can still come out the drain plugs. I have a piece of half inch outer diameter PVC tube crammed through the drain plug holes all the way to the firewall that has been waxed. Once the foam expands I will pull the PVC out and water will have a place to collect if there's a leak.

Hopefully tomorrow I can epoxy the floor in and start stitching the outer edge with a layer of 17 Oz. Then I'll drill a couple holes and pour the foam in once that cures.

Hopefully tomorrow I can epoxy the floor in and start stitching the outer edge with a layer of 17 Oz. Then I'll drill a couple holes and pour the foam in once that cures.

- Location

- woodridge IL

Dude, amazing work! Do you have a day job?! Seems like every hr you have an update on this!!! haha … can't wait to see this thing completed.. at this rate you will beat me and I didn't do any where near the amount of fiberglass work you did!I poured the remaining two part foam that I had which I thought would be a little more than I needed but it only did about three-quarters of the tray. I ordered some more and I'll pour it from the other end and it should fill the rest of it up. Where it did fill it's super solid.

View attachment 374051View attachment 374052View attachment 374053

- Location

- woodridge IL

It all makes sense now!! Lol keep it up!I work from home and spend a lot of time waiting on people, instead of youtube I do this lol.

- Location

- Northern michigan

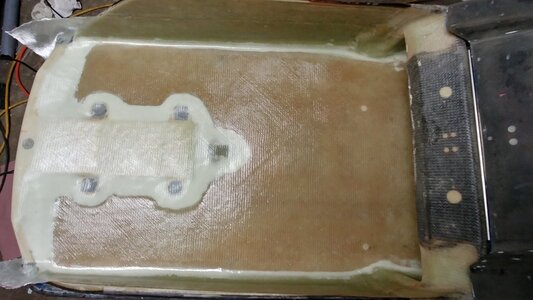

Looks like there is a lip around the pump bolt area and the flat. You can put a layer of thickened epoxy in that area (feathered) then put a strip (4" wide)of biax over it and gently roll that transition flat with a roller . The biax should be very light the lighter the better. Apply it dry and let it pull the resin it needs to wet out as you roll it from the thickened resin BTW you are doing a phenomenal job on this. And the above is only to help and not knitpick

Looks like there is a lip around the pump bolt area and the flat. You can put a layer of thickened epoxy in that area (feathered) then put a strip (4" wide)of biax over it and gently roll that transition flat with a roller . The biax should be very light the lighter the better. Apply it dry and let it pull the resin it needs to wet out as you roll it from the thickened resin BTW you are doing a phenomenal job on this. And the above is only to help and not knitpick

I may do that, Im just glad its stitched together without issue, and I think the transitions are fine for being under turf and an inch of padding, well see how it looks outside tomorrow.

Im also trying to keep the pump nuts accessible with minimal cutting so if there is ever an issue with one I can fix it, that is partially why the rear nut areas are flat like that.

I know it seems trivial but I stood on the tray this morning and doing that really helped me realize its actually coming together! Feels super solid and probably did not need the expandable foam, however I was doing it more for my through hull tubes than anything.

Next is prepping the engine bay for reinforcement and working on the tray gunwales to fatten them up.

I am thinking about going light on the engine bay, one layer of 17oz non biax under the engine area and another over the entire engine bay. Should be quite a bit lighter than a single layer of 1708 and stronger than 1208. If anyone doesnt think thats enough let me know.

The gunwales I am thinking a half inch square of foam running the edge should be enough, put a nice 45 bevel on the underside and a rounded edge and it should be good for glass I think.

I need to decide eventually what external controls I want, if any. Fuel selector, choke, primer, bilge. I could make a pocket to mount them in and rivet it in I suppose. I have been a less is more sort of guy and dont generally run a choke or primer but it may be advisable. Bilges have been a plug them in when I get to the lake sort of affair and that has been fine so far, I always pop the hood regardless before I start at the lake.

Next is prepping the engine bay for reinforcement and working on the tray gunwales to fatten them up.

I am thinking about going light on the engine bay, one layer of 17oz non biax under the engine area and another over the entire engine bay. Should be quite a bit lighter than a single layer of 1708 and stronger than 1208. If anyone doesnt think thats enough let me know.

The gunwales I am thinking a half inch square of foam running the edge should be enough, put a nice 45 bevel on the underside and a rounded edge and it should be good for glass I think.

I need to decide eventually what external controls I want, if any. Fuel selector, choke, primer, bilge. I could make a pocket to mount them in and rivet it in I suppose. I have been a less is more sort of guy and dont generally run a choke or primer but it may be advisable. Bilges have been a plug them in when I get to the lake sort of affair and that has been fine so far, I always pop the hood regardless before I start at the lake.