F

Freestyleriverrat

Guest

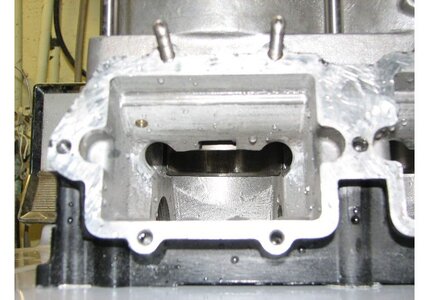

Head pipe: Front Cylinder

Once the manifold cleared the PV comfortably I just bolted the manifold to the head pipe and used a marker to trace a line on the bottom of the head pipe to give me a rough idea of where to start grinding. I used a 5in cut off wheel to gring away the big sections and used a 80 grit sanding bit followed by a 120 grit wheel. Took my time and was constantly checking and rechecking the fit. Used a sharpie to indicate where the valve hit, and did it a section at a time until the front PV cleared. I wante dto take my time on grinding b/c I want a smooth looking pipe.

I can already tell the rear PV is going to be a pain and take twice as long. I will try and document that one well b/c I will be cutting into the water jacket which can be a little shakey for some guys (like myself). Paul charges $450 for this mod and it is worth every penny!!!!! I may have him weld my water jacket up when his shop is up and running.

Once the manifold cleared the PV comfortably I just bolted the manifold to the head pipe and used a marker to trace a line on the bottom of the head pipe to give me a rough idea of where to start grinding. I used a 5in cut off wheel to gring away the big sections and used a 80 grit sanding bit followed by a 120 grit wheel. Took my time and was constantly checking and rechecking the fit. Used a sharpie to indicate where the valve hit, and did it a section at a time until the front PV cleared. I wante dto take my time on grinding b/c I want a smooth looking pipe.

I can already tell the rear PV is going to be a pain and take twice as long. I will try and document that one well b/c I will be cutting into the water jacket which can be a little shakey for some guys (like myself). Paul charges $450 for this mod and it is worth every penny!!!!! I may have him weld my water jacket up when his shop is up and running.

Attachments

Last edited by a moderator: