You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY Total loss or MSD TL upgrade box 270USD?

- Thread starter Christian_83

- Start date

- Location

- Glenmoore pa

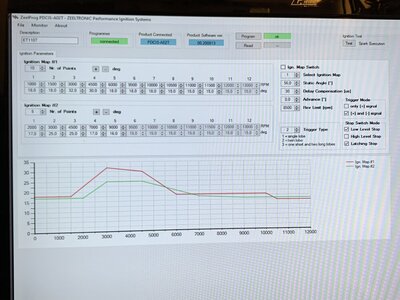

That’s the wax curve. It’ll work but if you go back a few pages and find my old 1107 curve you’ll have better results. More advance earlier and carry it out to 6k then drop quickly. I can send you the file if you want.Soo installede my zeeltronic and hooked it up too the pc, does this look right ? It’s Yamaha ET 1107 set up.

View attachment 404433

Will your 1107 curve work good on my 967?

That’s the wax curve. It’ll work but if you go back a few pages and find my old 1107 curve you’ll have better results. More advance earlier and carry it out to 6k then drop quickly. I can send you the file if you want.

- Location

- Glenmoore pa

I’m guessing it would work well. You’ll honestly want to just ask art what curve he recommends. My curve is just a zeel version of what he recommended for the MSD. I THINK the curve I used would actually be less aggressive on a stock stroke motor because the piston is closer to TDC at 32 degrees on a stock stroke compared to a 10mm stroker but I’m no expert there.Will your 1107 curve work good on my 967?

What if its already removed and im upgrading to the 2T?Just leave it on there, its designed to run the ignition like this

Yes please if you Will sende the curve, i was thinking if static angal / delay compensation / trigger mode. Burut sende the zeeltronic made for the kawa 750 sxi soo not sure is that is info match the Yamaha ???That’s the wax curve. It’ll work but if you go back a few pages and find my old 1107 curve you’ll have better results. More advance earlier and carry it out to 6k then drop quickly. I can send you the file if you want.

- Location

- England

I got chance to do some measuring with a k1100 flywheel and stator on the bench.

Using the same “eyeball” method I used to get my 750 elecs within 1°, I am getting around 70° static angle for the 1100 parts. The position of the pickup in the stator cover is the same for 750 and 1100 and indeed the covers are interchangeable, but the flywheels are very different.

flywheel band starts at 117° from tdc mark, subtract the 47° pickup position, and you have 70°

i have made a few different measurements using different methods, measuring flywheel with pickup and band aligned etc etc, and the result is the same.

the built in “idle” timing of the flywheel is 12° in my estimation, so the first thing I would do would be programme 70° Static and see if the factory installed timing marks align with the motor cranking (plugs out to make it smoother) with your strobe light set to 12°

if not, then tweak the static a degree or so either way.

if it’s wildly out then back to the drawing board

Using the same “eyeball” method I used to get my 750 elecs within 1°, I am getting around 70° static angle for the 1100 parts. The position of the pickup in the stator cover is the same for 750 and 1100 and indeed the covers are interchangeable, but the flywheels are very different.

flywheel band starts at 117° from tdc mark, subtract the 47° pickup position, and you have 70°

i have made a few different measurements using different methods, measuring flywheel with pickup and band aligned etc etc, and the result is the same.

the built in “idle” timing of the flywheel is 12° in my estimation, so the first thing I would do would be programme 70° Static and see if the factory installed timing marks align with the motor cranking (plugs out to make it smoother) with your strobe light set to 12°

if not, then tweak the static a degree or so either way.

if it’s wildly out then back to the drawing board

speedysprocket

Alex

- Location

- Chesapeake, VA

I thought you put zeeltronics on a BMW motorcycle when I first started reading that!..

- Location

- England

Haha nice. To be honest zeeltronic has been around a lot longer on bikes than it has on pwc!!

speedysprocket

Alex

- Location

- Chesapeake, VA

Haha nice. To be honest zeeltronic has been around a lot longer on bikes than it has on pwc!!

My dad has a BMW K1100, and I’ve never seen someone refer to a kawi 1100 as k1100..

- Location

- England

It’s nomenclature I use all the time when ordering parts to differentiate between kawi yam Polaris etc

my apologies

my apologies

- Location

- Michigan

Can someone tell me what the difference is between the PDCIS-02T and PDCIS-A02T... i have only used the 02T in the past and see the A02T now listed. What were the updates/changes.

Thanks

Sent from my SM-G975U using Tapatalk

Thanks

Sent from my SM-G975U using Tapatalk

Can someone tell me what the difference is between the PDCIS-02T and PDCIS-A02T... i have only used the 02T in the past and see the A02T now listed. What were the updates/changes.

Thanks

Sent from my SM-G975U using Tapatalk

A02T is slightly different physical size and shape, it has a tachometer output wire, and it can work without grinding the "third lump" off of the flywheel.

speedysprocket

Alex

- Location

- Chesapeake, VA

Since msd total loss is no more maybe one of you smart people can make it work with a traditional msd style flywheel and pickup plate. Don’t know if a Hall effect sensor could be used on a plate instead of being in the front cover

Sent from my iPhone using Tapatalk

MSD stopped making the TL CDI?!

Big Kahuna

Administrator

- Location

- Tuscaloosa, AL

Where you been?????? All that was talked about yesterday!!!!!!!!MSD stopped making the TL CDI?!

speedysprocket

Alex

- Location

- Chesapeake, VA

Where you been?????? All that was talked about yesterday!!!!!!!!

I only get alerts for this thread and a couple others. Just been too busy to read everything all the time.

- Location

- central florida

It's also claimed to have stronger spark at higher rpmA02T is slightly different physical size and shape, it has a tachometer output wire, and it can work without grinding the "third lump" off of the flywheel.

- Location

- Winter Park

It's also claimed to have stronger spark at higher rpm

Still waiting for someone to confirm- if anyone has actually done a back to back test.

Sent from my iPhone using Tapatalk

Christian_83

Xscream

- Location

- Denmark

Since msd total loss is no more maybe one of you smart people can make it work with a traditional msd style flywheel and pickup plate. Don’t know if a Hall effect sensor could be used on a plate instead of being in the front cover

Sent from my iPhone using Tapatalk

That was the original idea of this thread