- Location

- King of Prussia, PA

Ok well I was in the store yesterday for some other stuff and just took a picture of the valves! I was wrong on who made them. they are made by Guzzler! The store owner said most people don't know about them.

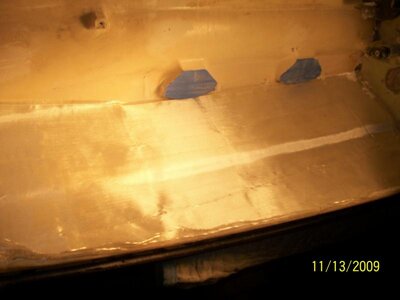

I will tell you one thing it is amazing how much water is not inside the boat when you have check valves on 2- 3/4" bildge hoses.

Alright, thanks. I'm gonna see if I can find a couple