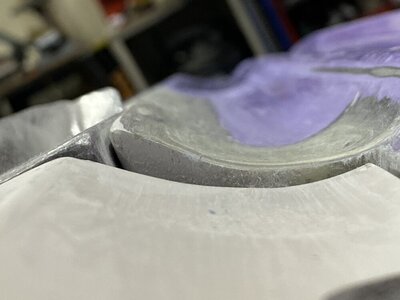

Alright. So at this point I've reinforced all of my hull. And installed my pump tunnel and aligned my pump.

To anyone using a Tom 21 tunnel. I would go the route I did the 3rd time to glue it in place.

Yes I aligned and glued my tunnel in 3 times. Third time is the charm and what I found to be the easiest route.

This is basically my first project of this kind and as I was told by several people anything fiberglass can be fixed. The first two times installing the tunnel with the pump aligned it was a headache. I was shimming, balancing, adding weights and clamps. This was a total headache, the slightest bump, and Id have to start over. I was browsing through Brapperdoodles Back From the DEAD FX-2 thread when I saw his pump mounted to the tunnel with allthread which I assumed he has using for his alignment. I later found out he was just using it to mount his pump to the tunnel. But seeing that is what gave me the idea for this.

You'll have open up some of the holes on the angle iron so the allthread can go through. I chose the allthread which was standard size (no metric althread) that was closest to size of oem superjet pump mounting bolts. I used a washer spread out the weight on the tunnel on top. It then torqued the pump to tunnel using the washers nuts and bolts to superjet torque specs 12/24 ftlbs. I am using brass yamaha SJ inserts for final installation as well as sj pump bolts hence SJ torque specs.

The Tom 21 tunnel has mounting hole marks. I lined my pump up to these before drilling and squared pump up to them. I set mine back a few millimeters to get the positions right.

With the pump hanging from the allthread you can adjust the four bolts for pitch up top as well as slide the angle iron forward or back. One thing to keep in mind when aligning is to keep an eye on the back of back of you pump and tunnel to make sure you axis of rotation is correct.

You can properly align you drives shaft, and have your tunnel be at 4 o'clock Instead of 12 o'clock where it needs to be. Make sense?

I used a cold fusion alignment tool. Placed locator pins in the bulk head. Installed cold fusion tool. Then torqued the alignment tool to FX-1 midshaft torque specs (I did this the third time lol).

I'm running a 96-07 SuperJet drive shaft in my 144 pump. I aligned it to the same depth into the engine bay as my stock Fx-1 Drive shaft.

More to come...

![IMG_5655[1963].jpg](/data/attachments/349/349481-9c3a35db516a5821a7f92fe1135453a3.jpg)

![IMG_5657[1962].jpg](/data/attachments/349/349482-59d87f025f8b233f1fdcfd26727aaac5.jpg)